A German Nanomaterials Research Institute Partners with Brother Furnace for a High Vacuum Tube Furnace

When advanced research calls for precision engineering, only the best

solutions can keep up with demanding needs. A German nanomaterials research

institute recently faced this challenge and selected Brother Furnace’s high vacuum tube furnace to enhance its capabilities.

Known for our expertise in designing and manufacturing custom high vacuum furnaces, we take pride in this collaboration, which underscores our commitment to delivering cutting-edge solutions for critical research applications.

This case study explores the institute’s requirements, the features of Brother Furnace’s products, and the transformative impact it had on their work.

The Client: A World-Leading Nanomaterials Research Institute

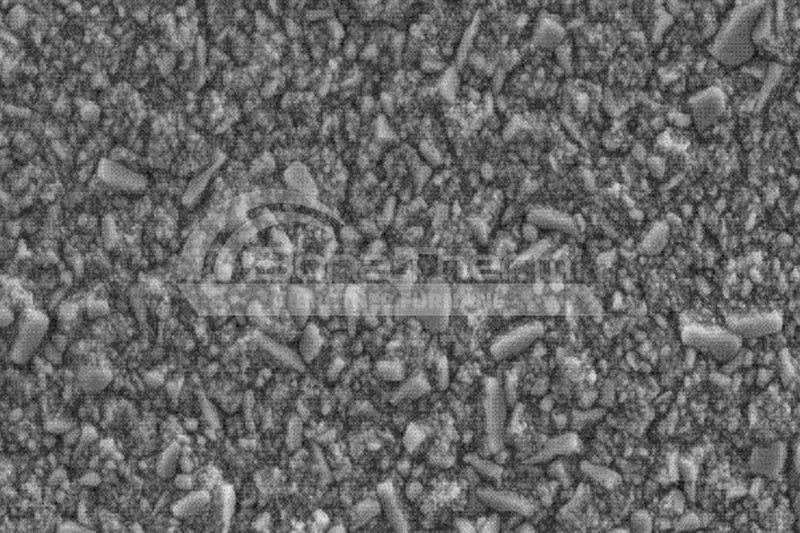

Located in Germany, the institute is a leader in nanomaterials research, renowned for its groundbreaking work in nanostructures, thin films, and quantum materials.

Their projects include developing advanced materials for use in electronics, renewable energy, and medical devices. The institute’s mission is to push the boundaries of material science, and its success depends on access to the latest technological tools.

Nanomaterials research often involves:

● Precision-controlled environments for processes like vacuum heat treatment and thin-film deposition.

● Extreme temperatures with exact temperature uniformity to achieve desired material properties.

● Specialized equipment for high-temperature synthesis and sintering in high vacuum applications.

As the institute sought to expand its research scope, it needed a furnace

capable of meeting these rigorous requirements. Their search led them to Brother

Furnace, a trusted provider of high vacuum systems for research and industrial

applications.

Brother Furnace: A Trusted Partner for Advanced Research

Brother Furnace has established itself as a global leader in the design and manufacturing of vacuum tube furnaces and high vacuum systems. Our expertise spans decades, and we specialize in creating tailored solutions for laboratories, research institutions, and industrial facilities.

Key Features of the High Vacuum Tube Furnace

The high vacuum tube furnace selected by the German institute stands out for its:

High-Temperature Vacuum Tube Sintering Furnace

Designed to reach temperatures up to 1,600°C, this furnace ensures consistent performance for sintering nanomaterials under high vacuum conditions.

Exceptional Temperature Uniformity

The uniform temperature distribution is critical in material research. Our furnaces maintain precise control, enabling reproducible results even for highly sensitive experiments.

Advanced Controllers

Equipped with the latest in automation technology, the furnace allows for customizable heating profiles, real-time monitoring, and precise control of the entire process.

Wide Pressure Ranges

The furnace supports ultra-high vacuum as well as controlled atmosphere

conditions, making it adaptable for various high vacuum applications.

Energy Efficient High Vacuum Furnaces

Sustainability is at the core of our design philosophy. The furnace’s energy-efficient design minimizes operational costs without compromising performance.

Bespoke Designs

Each furnace can be tailored to the client’s unique needs. For the institute, this meant compatibility with existing lab equipment and additional customization to support advanced material characterization.

Understanding the Client’s Challenges

The institute faced several challenges that required a robust solution:

Precision Temperature Control

Achieving reliable results in nanomaterials research demands extreme temperature stability and uniformity across the sample.

Vacuum Heat Treatment Compatibility

Processes like thin-film deposition and advanced material synthesis required a furnace capable of maintaining consistent vacuum conditions during heating.

Scalability for Research and Pre-Industrial Applications

The institute needed a furnace that could serve both laboratory-scale

experiments and pilot-scale material production.

Integration with Analytical Equipment

The furnace had to seamlessly integrate with high-precision instruments for in-situ measurement and analysis.

Brother Furnace’s high vacuum tube furnace was designed to address all these challenges, making it the perfect choice for the institute’s needs.

Delivering a Tailored Solution

After thorough consultations, we developed a customized high vacuum tube furnace tailored to the institute’s specifications. The key enhancements included:

● Optimized Vacuum Heat Treatment: The furnace was engineered to maintain ultra-high vacuum levels, ensuring clean and oxidation-free environments for material processing.

● Enhanced Automation: Integrated advanced controllers enabled programmable heating cycles, data logging, and real-time feedback for precise process management.

● Wide Pressure Range Support: The furnace supported both high vacuum and controlled atmosphere operations, giving researchers maximum flexibility in designing experiments.

The Impact: Transforming Research Capabilities

The installation of the high vacuum tube furnace marked a turning point for the institute. The furnace significantly enhanced their research capabilities, enabling them to:

Achieve Precision Results

The furnace’s exceptional temperature uniformity allowed researchers to replicate results consistently, a critical requirement for peer-reviewed research.

Explore New Materials

With its ability to handle extreme temperatures and maintain stable vacuum

conditions, the furnace opened new possibilities for exploring advanced

materials, including thin films and nanostructures.

Improve Efficiency

Thanks to its energy-efficient design and furnace automation solutions, the institute reduced energy consumption and streamlined workflows, saving time and resources.

Enhance Collaboration

The furnace’s advanced features enabled collaboration with other institutions and industrial partners, as its performance was suitable for both fundamental research and applied material development.

Accelerate Research Outcomes

By enabling real-time data collection and analysis during experiments, the furnace helped researchers reduce the time from experimentation to publication.

Broader Applications of the High Vacuum Tube Furnace

While this case study focuses on nanomaterials research, the high vacuum tube furnace is a versatile tool with applications across numerous fields:

● Laboratory Vacuum Furnaces: Ideal for academic and research institutions conducting precision material studies.

● Industrial Vacuum Furnaces: Suitable for applications like high-temperature sintering and vacuum heat treatment of advanced ceramics and alloys.

● Advanced Material Production: Used in industries like electronics, aerospace, and renewable energy for developing next-generation materials.

Why Choose Brother Furnace?

This collaboration exemplifies Brother Furnace’s dedication to delivering

cutting-edge solutions tailored to our clients’ needs. Here’s why researchers

and industrial leaders trust us:

Custom High Vacuum Furnaces

We specialize in creating bespoke designs to meet the unique demands of each client, whether for academic research or industrial production.

Commitment to Quality

Our high vacuum systems are engineered to deliver precision, reliability, and durability, ensuring consistent performance over time.

Energy Efficiency

We design energy-efficient high vacuum furnaces that minimize operational costs while maintaining optimal performance.

Advanced Technology

From advanced controllers to furnace automation solutions, our furnaces incorporate the latest innovations to enhance user experience and process efficiency.

Comprehensive Support

Our team provides end-to-end support, from consultation and installation to training and maintenance, ensuring a seamless experience for our clients.

Welcome to a Bright Future with Brother Furnace!

The success of this project highlights the transformative potential of a well-designed high vacuum tube furnace. For the German nanomaterials research institute, the furnace not only solved immediate challenges but also positioned them to lead in the rapidly evolving field of nanotechnology.

Brother Furnace is proud to support innovation across industries with our advanced high vacuum systems. Whether you are conducting groundbreaking research or developing next-generation materials, our high vacuum tube furnace offers the precision, reliability, and efficiency you need to succeed.

Are you ready to take your research or production to the next level? Reach out to Brother Furnace to explore how our high vacuum tube furnace and other custom high vacuum furnaces can be tailored to meet your specific needs.