Belgium Semiconductor Laboratory Introduces a Slide-Rapid Cooling Tube Furnace

In the dynamic world of semiconductor research, where precision, efficiency,

and adaptability are crucial, laboratories are continuously seeking advanced

equipment to maintain their competitive edge.

At Brother Furnace, we pride ourselves on manufacturing high-performance furnaces tailored to meet the evolving needs of advanced industries, especially in semiconductor research and development.

Recently, a prominent semiconductor materials laboratory in Belgium selected our slide-rapid cooling tube furnace to address its need for enhanced cooling control, underscoring the lab's commitment to innovation.

Belgium’s position as a hub of technological advancement is well known, with its semiconductor sector driving forward global progress in electronics. The lab in question has been actively researching new semiconductor materials to enhance device functionality and power efficiency.

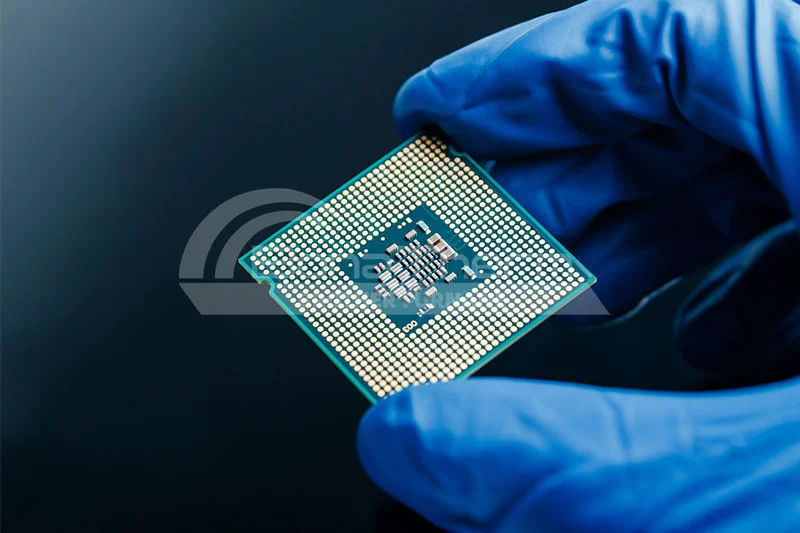

Specializing in cutting-edge materials such as gallium nitride (GaN) and silicon carbide (SiC), the lab relies on a precise, rapid cooling process to stabilize these materials post-treatment.

To achieve this level of control, they needed equipment capable of offering

rapid cooling along with exact temperature regulation, features that are vital

for producing high-quality, durable semiconductor wafers and other

materials.

The Need for the Slide-Rapid Cooling Tube Furnace

In the semiconductor industry, cooling speed and uniformity are critical parameters affecting material quality. For this lab, maintaining stringent cooling requirements was essential for material stability and reducing internal stress.

Prior cooling systems required extended time to cool materials properly, often causing bottlenecks in the process flow and affecting project timelines. After a thorough review of their production process, the lab's team identified the need for a more advanced furnace solution that could ensure rapid cooling to maintain high throughput.

They sought out Brother Furnace’s slide-rapid cooling tube furnace based on our reputation for reliable, high-performance equipment, as well as our commitment to creating customized solutions for unique industry challenges. Brother Furnace is known for efficiency in rapid cooling and precise temperature control, which perfectly aligns with the lab’s requirements.

Features of the Slide-Rapid Cooling Tube Furnace

The slide-rapid cooling tube furnace stands out for its unique design

tailored to applications requiring rapid thermal changes. Below are some of the

key features that make it the ideal choice for semiconductor applications:

Accelerated Cooling Mechanism

Engineered with a high-capacity cooling system, the slide-rapid cooling tube furnace enables the lab to reduce cooling times significantly. This system allows the lab to achieve faster process turnaround, directly improving productivity and reducing wait times for crucial steps in wafer production.

Temperature Precision

Semiconductor materials demand accurate temperature control, especially during cooling. Brother Furnace offers precise, stable cooling temperatures, ensuring material properties are preserved and consistent across batches.

Slide Mechanism for Swift Operation

The unique slide design allows the lab to easily load and unload materials, making it ideal for laboratories with high sample throughput. This mechanism minimizes downtime, letting researchers seamlessly transition between heating and cooling phases without compromising on performance.

Durability and Reliability

Constructed from premium materials and designed with heavy usage in mind,

slide-rapid cooling tube furnaces are built to handle continuous operation,

making them an asset for high-demand labs.

This durability aligns with Brother Furnace’s dedication to high-quality manufacturing, ensuring longevity and stable performance in rigorous research environments.

Implementation and Initial Experiences

Upon receiving the slide-rapid cooling tube furnace, the lab's engineers noted the straightforward installation process. Brother Furnace’s support team worked closely with the lab to ensure seamless integration, minimizing downtime and enabling the lab to quickly begin its initial testing phase. The setup process was customized to fit the lab’s workflow, which further increased the efficiency of the operation.

The laboratory team was particularly impressed by the system's smooth slide functionality, which allowed for quick loading and unloading—an essential feature given their high material turnover rate. Additionally, the cooling system’s efficiency immediately stood out, reducing material cooling time by nearly 40% compared to their previous setup. This allowed researchers to conduct tests and analyze results faster, increasing productivity and shortening project timelines.

Customer Feedback and Results

Since implementing the slide-rapid cooling tube furnace, the lab has reported

noticeable improvements in both process efficiency and material quality.

According to the head of the lab’s R&D department, the furnace’s precise

temperature control has led to fewer thermal inconsistencies, which previously

impacted wafer yield rates. By achieving consistent results in its cooling

process, the lab has seen a rise in output quality, which has further enhanced

its reputation in the industry.

Another notable feedback was the significant decrease in cooling cycle times. What used to take an hour with traditional equipment now takes a fraction of that time, allowing the lab to conduct more tests within a given timeframe. This increase in testing capacity has enabled the lab to accelerate project cycles and deliver results to their clients faster, making the tube furnace an invaluable addition to their facility.

The lab’s senior technician also appreciated Brother Furnace’s ongoing support, mentioning how the technical guidance from our team proved invaluable, especially during the adaptation phase. This support helped their engineers optimize the slide-rapid cooling tube furnace's operation for their unique requirements and maximize its potential for semiconductor applications.

Long-Term Benefits and Outlook

Looking ahead, the Belgian semiconductor lab is optimistic about the advantages slide-rapid cooling tube furnaces will continue to bring. With this furnace, they now can explore advanced materials requiring precise thermal management without compromising on speed. The improved cooling times and precise temperature control have provided the lab with the flexibility to expand its research scope and take on more challenging projects.

This project has not only benefitted the Belgian lab but has also reinforced Brother Furnace’s reputation as a trusted cooperative partner in the high-tech semiconductor industry. Our slide-rapid cooling tube furnace has proven to be an effective solution for labs that require both reliability and speed, making it a valuable tool in semiconductor research.

Partnering for Progress with Brother Furnace

The success of the cooperative partners at the Belgian semiconductor lab

underscores the essential role advanced thermal equipment plays in today’s

cutting-edge industries.

At Brother Furnace, we take pride in our commitment to providing high-quality, reliable solutions that empower laboratories to push the boundaries of research and innovation. Our collaboration with this lab not only facilitated immediate improvements in their cooling process but also showcased how slide-rapid cooling tube furnaces can transform laboratory operations, enhancing both efficiency and output quality.

As a leading manufacturer of thermal solutions, Brother Furnace is dedicated to helping clients achieve their goals by providing tailor-made products that address specific challenges.

The success of the cooperative partner at this lab is a testament to the impact Brother Furnace strives to make. Brother Furnace looks forward to continuing its journey of innovation, meeting the needs of laboratories around the world, and supporting the semiconductor industry’s drive for excellence.