Ceramic Fiber Muffle Furnaces: The Ultimate Guide for Buyers

A ceramic fiber muffle furnace is an essential tool in many industries,

offering precise temperature control and superior insulation for

high-temperature processes.

These furnaces are widely used for heat treatment, sintering, material testing, and more, owing to their durability, efficiency, and flexibility. Designed with cutting-edge ceramic fiber insulation, they not only minimize energy loss but also ensure consistent performance over time.

In this comprehensive guide, we’ll delve into the features and benefits of ceramic fiber muffle furnaces, explore their applications across various sectors, and provide practical tips for choosing and maintaining the right furnace for your needs.

Whether you're searching for an energy-efficient muffle furnace or a custom muffle furnace, Brother Furnace will equip you with all the necessary knowledge to make an informed decision.

Key Features and Benefits

1. Energy Efficiency and Reduced Heat Loss

The primary advantage of a ceramic fiber muffle furnace lies in its energy

efficiency. The ceramic fiber insulation minimizes heat loss by containing high

temperatures within the chamber. This not only reduces energy consumption but

also cuts operational costs over time. Compared to traditional muffle furnaces,

models with ceramic fiber insulation are more sustainable and

cost-effective.

For businesses looking to lower their carbon footprint, an energy-efficient muffle furnace is an excellent investment. These furnaces often come with optimized power consumption settings, ensuring that energy use is kept to a minimum without compromising performance.

2. Uniform Temperature Distribution

Achieving uniform temperature across the chamber is critical in processes like sintering, annealing, and material testing. High-temperature muffle furnaces are designed to provide even heat distribution, ensuring consistent results. The advanced heating elements and insulated chambers of these furnaces ensure minimal temperature fluctuations, even during extended operations.

This uniformity makes a muffle furnace with ceramic fiber insulation ideal for applications requiring high precision, such as the production of ceramics, heat treatments, and laboratory experiments.

3. Rapid Heating and Cooling

Time is a valuable resource in any industrial or research setting. A digital muffle furnace with ceramic fiber insulation is capable of rapid heating and cooling, reducing cycle times significantly. This feature enhances productivity and allows users to complete processes faster without sacrificing quality.

4. Durability and Resistance to Thermal Shock

Durability is a key consideration for any high-temperature furnace. Ceramic

fiber muffle furnaces are built to withstand repeated thermal cycling, thanks to

their resistance to thermal shock. This durability reduces the frequency of

repairs and replacements, ensuring a longer lifespan and lower maintenance

costs.

5. Low Maintenance Requirements

Unlike traditional furnaces, which may require frequent upkeep, muffle furnaces with ceramic fiber insulation are relatively low-maintenance. Their robust design and quality materials ensure reliable performance, even under heavy use. Routine cleaning and occasional inspections are usually sufficient to keep the furnace in optimal condition.

Applications and Uses

1. Laboratory Applications

Laboratory muffle furnaces are indispensable for tasks such as material testing, sample preparation, and thermal decomposition analysis. Their precise temperature control and compact design make them ideal for research institutions, universities, and quality control labs.

2. Industrial Processes

In industrial settings, high-temperature muffle furnaces are used for a variety of applications, including heat treatment, sintering, and annealing. These processes are crucial in manufacturing high-quality components for industries such as automotive, aerospace, and electronics.

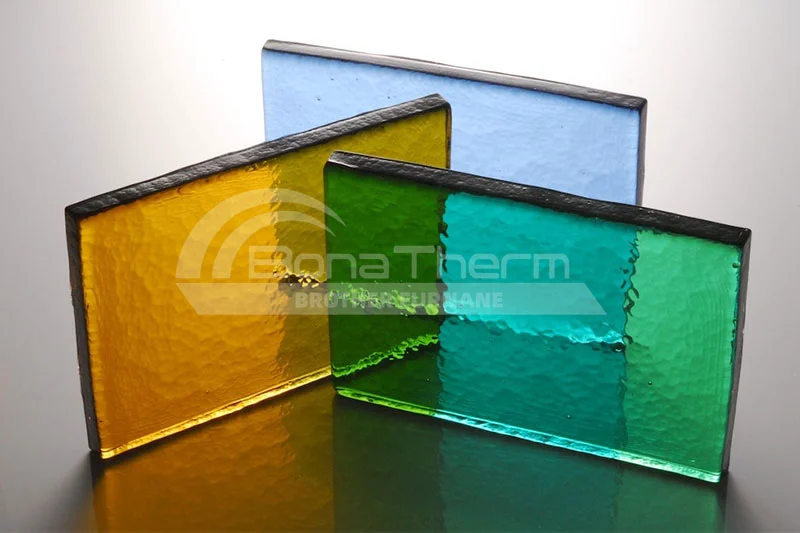

3. Ceramics and Glass Industry

A muffle furnace for ceramics is a vital tool for producing ceramic and glass

products. These furnaces are used for firing, glazing, and other

high-temperature treatments, ensuring the integrity and quality of the final

products. Their precise temperature control and uniform heat distribution make

them ideal for these intricate processes.

4. Dental and Medical Applications

Dental labs and medical facilities frequently use compact muffle furnaces for casting, sintering, and sterilization. Their ability to operate in confined spaces while delivering consistent results makes them invaluable in these specialized fields.

5. Research and Development

R&D departments benefit greatly from custom muffle furnaces, which can be tailored to meet specific experimental requirements. Whether it’s developing new materials or optimizing production processes, these furnaces provide the flexibility and precision needed for innovation.

How to Choose the Right Muffle Furnace

Selecting the right ceramic fiber muffle furnace involves a careful evaluation of your needs and understanding the available options. Here’s a step-by-step guide:

Determine Temperature Requirements

Identify the maximum and minimum temperatures your processes require. A high-temperature muffle furnace is essential for applications that demand extreme heat, while a standard model may suffice for less demanding tasks.

Assess Chamber Size and Capacity

Consider the size and volume of materials you’ll be processing. A custom muffle furnace can be designed to match specific capacity requirements, ensuring efficient operation.

Evaluate Heating Element Types

Different applications may require different heating elements. Consult with

Brother Furnace to select a furnace with the appropriate element for your

needs.

Analyze Energy Efficiency Ratings

Investing in an energy-efficient muffle furnace can significantly reduce operational costs. Look for models with high energy efficiency ratings to maximize savings over time.

Review Control Systems

Modern digital muffle furnaces offer programmable control systems, allowing for precise temperature adjustments and automated operation. This feature is especially useful for processes requiring consistent conditions.

Check Safety Features

Safety should always be a priority. Ensure the furnace is equipped with essential muffle furnace safety features, such as over-temperature protection, emergency shutdown systems, and insulated exteriors.

Compare Warranty and Support

Reliable after-sales support is crucial for long-term satisfaction. Choose a supplier like Brother Furnace that offers a comprehensive warranty and excellent customer service.

Maintenance and Safety Tips

Proper maintenance and adherence to safety guidelines are essential for

prolonging the life of your ceramic fiber muffle furnace and ensuring safe

operation.

1. Routine Inspection and Cleaning

Regularly inspect the furnace for signs of wear or damage. Clean the chamber and heating elements to prevent residue buildup and maintain efficiency.

2. Proper Loading and Unloading

Avoid overloading the furnace, as this can lead to uneven heating and potential damage. Use appropriate tools for loading and unloading to protect both the furnace and the materials.

3. Temperature Calibration

Periodic calibration ensures that your digital muffle furnace maintains accurate temperature readings. This is critical for applications requiring precise thermal control.

4. Safe Material Handling

Store and handle materials properly to avoid contamination and ensure compatibility with the furnace.

5. Use Personal Protective Equipment

Always wear gloves, goggles, and heat-resistant clothing when operating the furnace to protect against burns and other injuries.

Conclusion

A ceramic fiber muffle furnace is an indispensable tool for industries and

laboratories requiring high-temperature precision and efficiency. From energy

savings to durability, these furnaces offer numerous benefits that make them a

worthwhile investment.

By understanding their features, applications, and maintenance requirements, you can choose the perfect furnace for your specific needs.

If you’re in the market for a laboratory muffle furnace, an industrial muffle furnace, or a custom muffle furnace, Brother Furnace is here to help. We specialize in providing high-quality, energy-efficient muffle furnaces tailored to diverse applications.

Explore our product range or contact us today for expert guidance and personalized solutions.

Elevate your heat treatment processes—choose Brother Furnace for unmatched quality and performance!