Choosing the Right Mini Tubular Furnace for Laboratory and Industrial Applications

One of the most versatile and reliable tools is the mini tubular furnace.

Despite its compact size, this powerful furnace delivers exceptional

performance, making it ideal for small-scale laboratory applications, research

experiments, and even certain industrial processes where space is limited but

precision is crucial.

This article will delve into the features and functionality of mini tubular

furnaces, offering insights into how they operate and the key factors to

consider when selecting the right one for your specific needs.

What is a Mini Tubular Furnace?

A mini tubular furnace is a high-temperature, small-scale furnace designed to heat materials in a tube-shaped chamber. These furnaces are widely used for a variety of laboratory and industrial applications, including materials testing, sintering, heat treatment, and even small-batch production.

The primary advantage of mini tubular furnaces is their ability to provide precise control over temperature and atmosphere, essential for experiments that require controlled conditions for optimal results.

Mini tubular furnaces are designed to accommodate different tube diameters and lengths, allowing for flexibility in the types of experiments or materials processed. Their small size makes them ideal for laboratories, educational institutions, and industries where space is limited but high performance is necessary.

How Does a Mini Tubular Furnace Work?

The mini tubular furnace consists of a cylindrical heating element that

surrounds a metal or ceramic tube. The tube is where the material to be heated

is placed, and it is often made from materials that are resistant to high

temperatures, such as quartz or alumina.

These furnaces can reach temperatures up to 1,600°C or more, depending on the specific model, and offer the ability to control the atmosphere inside the tube. For example, some mini tubular furnaces can provide a vacuum environment or allow for the introduction of inert or reactive gases, making them suitable for processes like sintering, annealing, or materials testing.

Key Considerations When Choosing a Mini Tubular Furnace

When selecting a mini tubular furnace for your application, there are several important factors to consider to ensure that it meets your specific needs:

Temperature Range and Uniformity

The first thing to look for is the maximum temperature the furnace can reach and how uniformly it can distribute heat. For high-precision work, such as research or material synthesis, even heat distribution across the tube is essential.

Atmosphere Control

Many processes require a controlled atmosphere, such as inert gases, reducing gases, or even a vacuum. If your application demands specific gas environments, ensure that the furnace allows for gas flow control or has a vacuum capability. A well-controlled atmosphere is critical for reactions and sintering processes.

Tube Size and Material Compatibility

The size of the tube, as well as the material compatibility, should be

tailored to the specific type of work you plan to conduct. For example, certain

materials require larger tubes for larger samples, while others may require a

more compact design. The choice of tube material is also critical to prevent

contamination and ensure the longevity of the furnace.

Safety Features

The safety of laboratory staff and the protection of valuable samples are of utmost importance. Ensure that the mini tubular furnace is equipped with appropriate safety features, such as temperature overrun protection, automatic shut-off, and gas leak detection if using reactive gases. This helps to prevent accidents and ensure smooth operations.

Applications of Mini Tubular Furnaces

Mini tubular furnaces are highly versatile and can be used in a variety of applications, such as:

● Materials Synthesis: Sintering and annealing materials at precise temperatures for research in the fields of ceramics, metals, and composites.

● Semiconductor and Electronics: Fabrication and testing of materials and components in controlled environments, crucial for the electronics industry.

● Metal Heat Treatment: Heat treatment of metals, including processes like tempering or brazing, requiring precise control over temperature and atmosphere.

● Research and Development: Ideal for small-scale testing and experiments in academic research or industrial R&D.

Brother Furnace's Mini Tubular Furnace Solutions

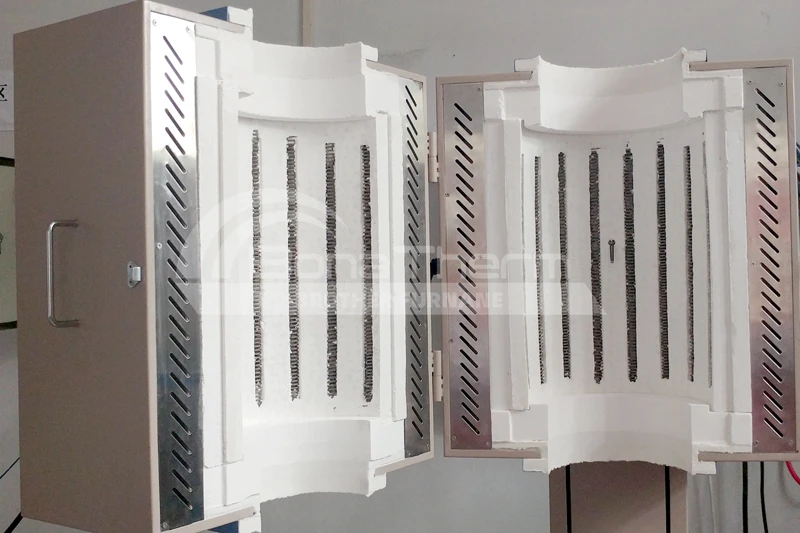

Brother Furnace offers a range of mini tubular furnaces designed to meet the

highest standards of performance and safety. Our furnaces are equipped with

advanced temperature control systems that provide uniform heat distribution

across the tube, and they come with optional features like gas flow control and

vacuum capabilities, making them ideal for a wide range of laboratory and

industrial applications.

The compact design of our mini tubular furnaces does not compromise on performance. Whether you’re conducting material synthesis, testing, or small-batch production, Brother Furnace's products offer a reliable and cost-effective solution for all your heating needs.

Conclusion

When it comes to selecting a mini tubular furnace, it’s essential to consider factors like temperature control, atmosphere capabilities, safety features, and compatibility with the materials you plan to process. With the right furnace, you can achieve precise and reliable results for a variety of laboratory and industrial applications.

Brother Furnace offers top-quality mini tubular furnaces with advanced features and reliable performance, making them an excellent choice for professionals who need consistent results in a small-scale, controlled heating environment.

For more information or to request a quote, contact us now and discover how our mini tubular furnaces can support your research and production needs.