High-Temperature Pyrolysis: The Essential Role of Tube Furnaces

High-temperature pyrolysis is a transformative process that effectively breaks down organic materials through thermal decomposition, playing a pivotal role in waste management, energy recovery, and material processing. For industries looking to harness the benefits of pyrolysis, the right equipment is crucial.

Among the most effective options is the high-temperature pyrolysis tube furnace, designed to deliver precise thermal conditions essential for optimal

results. As a leading manufacturer, Brother Furnace specializes in producing

high-quality pyrolysis equipment that meets diverse industrial needs.

Understanding High-Temperature Pyrolysis

High-temperature pyrolysis refers to the thermal decomposition of organic materials in the absence of oxygen, a process that generates valuable products such as biofuels, biochar, and various chemical feedstocks. The pyrolysis process can be categorized into different types:

Fast Pyrolysis: This method emphasizes rapid heating and quick product yield, ideal for generating bio-oil and biochar from biomass. Fast pyrolysis typically operates at temperatures between 450°C and 600°C, facilitating swift conversion and maximizing output.

Slow Pyrolysis: In contrast, slow pyrolysis involves prolonged exposure to heat, which allows for a more extensive breakdown of organic materials. Operating at lower temperatures (around 300°C to 500°C), slow pyrolysis is effective for producing charcoal and maximizing carbon content.

Flash Pyrolysis: Characterized by extremely short reaction times, flash pyrolysis employs high heating rates and is typically used for producing liquids from solid feedstocks. This method requires specialized equipment to handle rapid thermal changes.

The effectiveness of these processes heavily relies on temperature control, making a high-temperature furnace for pyrolysis essential in achieving high yields and quality outputs.

What is a Tube Furnace?

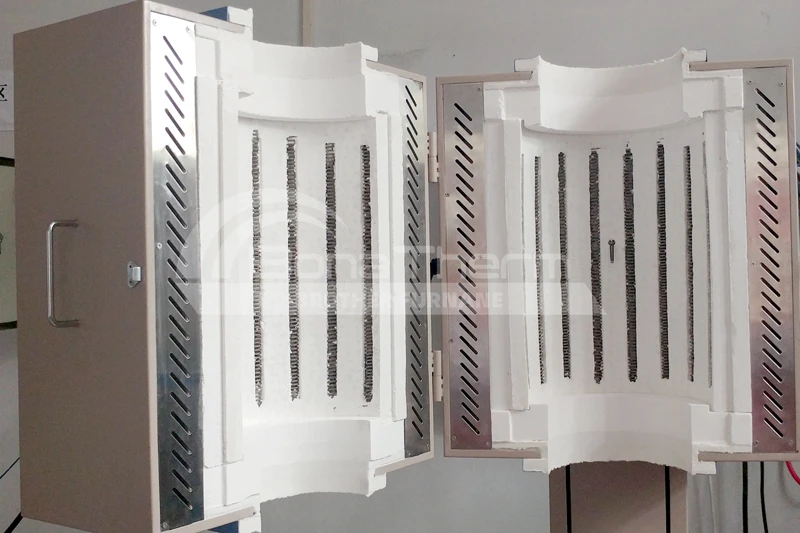

A tube furnace is a specialized piece of equipment designed for

high-temperature applications, particularly for pyrolysis. It features a

cylindrical chamber that allows for efficient heating of materials. Key

components of a tube furnace include:

Heating Elements: These are responsible for generating the necessary heat to facilitate pyrolysis, often made from high-grade materials that can withstand extreme temperatures.

Thermocouples: Precision thermocouples are critical for monitoring temperature within the chamber, ensuring that conditions remain optimal for the pyrolysis process.

Gas Flow System: Maintaining an inert atmosphere is crucial during pyrolysis to prevent combustion. A gas flow system allows for the introduction of inert gases like nitrogen or argon, enhancing safety and efficiency.

The operation of a tube furnace for pyrolysis is straightforward: materials are placed in the chamber, heated uniformly, and subjected to controlled pyrolysis conditions. This design ensures consistent results, making it an invaluable piece of advanced pyrolysis equipment.

Key Features of High-Temperature Pyrolysis Tube Furnaces

When selecting a tube furnace for pyrolysis, it's crucial to consider several key features:

Temperature Range: A high-temperature pyrolysis tube furnace typically reaches temperatures above 1000°C, which is critical for effective thermal decomposition. The ability to sustain such high temperatures ensures the complete breakdown of complex organic compounds.

Material Compatibility: The tube furnace must withstand corrosive by-products

generated during pyrolysis, ensuring durability and longevity. High-quality

materials in the construction of the furnace can significantly enhance its

lifespan.

Energy Efficiency: Investing in a high-efficiency tube furnace not only reduces operational costs but also minimizes environmental impact, aligning with sustainability goals. Energy-efficient designs can lead to significant savings over time.

Scalability: For industries looking to expand their operations, the scalability of a tube furnace is vital. Continuous pyrolysis furnaces can be designed to handle larger volumes of material, providing flexibility for growing businesses.

Applications and Industries

High-temperature pyrolysis has significant implications across various sectors, including:

Chemical Processing: In chemical processing industries, pyrolysis enables the recycling of plastics and other materials into useful chemicals. This process helps in reducing the dependency on fossil fuels and supports the transition to a circular economy.

Materials Science: The materials science sector benefits from pyrolysis by

providing novel materials for advanced applications. For example, carbon black

produced through pyrolysis can be used in tire manufacturing and as a

reinforcing agent in rubber products.

Energy Production: Pyrolysis can also contribute to energy production through the generation of biofuels. The conversion of biomass into bio-oil provides a renewable energy source that can be further processed into transportation fuels.

Specific uses within these industries include biochar production, which enhances soil health and sequesters carbon, and chemical recycling, which contributes to sustainability and resource recovery.

Choosing the Right Tube Furnace for Your Needs

Selecting the right tube furnace involves considering multiple factors:

Temperature Range: Depending on the materials being processed, the required temperature range may vary. Ensure the chosen furnace meets these specifications.

Size and Capacity: The physical dimensions of the tube furnace and its

capacity to handle specific volumes of material are essential. Larger operations

may require a continuous pyrolysis furnace to manage high throughput.

Material Selection: The materials used in the construction of the furnace impact its performance and durability. High-quality alloys and insulation materials should be prioritized.

Customization Options: Manufacturers like Brother Furnace offer custom pyrolysis tube furnaces tailored to specific operational needs, allowing businesses to optimize their processes for unique applications.

Manufacturer Reputation: Selecting a reputable pyrolysis furnace manufacturer is crucial. Look for suppliers with proven track records and positive customer testimonials to ensure reliability and quality.

Benefits of Investing in High-Quality Pyrolysis Equipment

Investing in high-quality pyrolysis equipment, such as a laboratory pyrolysis furnace or an industrial pyrolysis furnace, offers numerous advantages:

Long-Term Cost Savings: While the initial investment may be higher, high-quality equipment typically offers better performance and durability, leading to lower operational costs over time.

Enhanced Efficiency and Productivity: Advanced pyrolysis equipment can

significantly improve process efficiency, allowing for higher yields and reduced

downtime, which translates to greater overall productivity.

Improved Product Quality and Consistency: Consistent temperature control and uniform heating provided by a high-temperature furnace for pyrolysis result in higher quality outputs, enhancing market competitiveness.

Environmental Compliance: Utilizing efficient pyrolysis systems can help businesses meet environmental regulations and standards, thereby improving sustainability and corporate responsibility.

Maintenance and Support

To ensure the longevity and optimal performance of your tube furnace, regular maintenance is essential. Here are some tips:

Routine Inspections: Conduct regular inspections to identify potential wear and tear, ensuring any issues are addressed promptly.

Temperature Calibration: Regularly calibrate thermocouples and heating elements to maintain accurate temperature readings.

Cleaning: Keep the tube clean to prevent contamination and ensure efficient heat transfer.

Manufacturer Support: If you purchase a high-temperature pyrolysis tube furnace, Brother Furnace will provide you with the most prompt service.

Brother Furnace Looks Forward to Working with You!

High-temperature pyrolysis represents a key technology for waste management,

energy recovery, and material processing. The role of tube furnaces in this

process cannot be overstated, as they provide the precise thermal conditions

required for successful pyrolysis. Investing in high-quality pyrolysis

equipment, such as those offered by Brother Furnace, not only enhances

operational efficiency but also contributes to sustainability goals.

For businesses looking to optimize their pyrolysis processes, Brother Furnace encourages you to explore our range of advanced pyrolysis systems.

Welcome to contact us for more information or to request a quote.