Quartz Tube Furnaces: Precision Heating for Advanced Applications

In the rapidly evolving world of advanced material processing, precision and

reliability are paramount. Brother Furnace has long been at the forefront of

providing high-quality heat treatment solutions, and one of its flagship

products—quartz tube furnaces—is setting the standard for a wide range of

industrial applications.

Whether for research labs, semiconductor manufacturing, or material synthesis, Brother Furnace’s quartz tube furnaces offer unparalleled heating precision, exceptional thermal stability, and versatility.

This article will explore the features and benefits of quartz tube furnaces, focusing on their importance in advanced applications, their technical specifications, and how they contribute to the efficiency of various industrial processes.

What Are Quartz Tube Furnaces?

A quartz tube furnace is a type of laboratory or industrial furnace that

utilizes a quartz tube as the heating chamber. These furnaces are designed to

provide controlled and uniform heating for processes that require high

temperatures and precise temperature control. The quartz tube, made from

high-purity silicon dioxide (SiO₂), is chosen for its excellent resistance to

high temperatures, chemical inertness, and ability to withstand harsh processing

environments.

Typically, a quartz tube furnace is used for a wide array of applications, including chemical vapor deposition (CVD), material synthesis, thermal annealing, and high-temperature sintering processes.

Brother Furnace has engineered quartz tube furnaces to offer both consistent performance and the adaptability needed to meet the diverse demands of modern industrial applications.

Key Features of Brother Furnace’s Quartz Tube Furnaces

High-Temperature Performance Brother Furnace’s quartz tube furnaces are capable of reaching very high temperatures, often exceeding 1500°C (2732°F). This high-temperature capability makes them ideal for applications in material science, semiconductor manufacturing, and other industries where precise thermal treatment is crucial.

Advanced Temperature Control

One of the standout features of Brother Furnace’s quartz tube furnaces is the precise temperature control system. These furnaces are equipped with state-of-the-art temperature controllers and sensors that ensure even heat distribution and allow users to set and maintain temperatures with high accuracy. The result is consistent, reproducible outcomes, which is essential for processes like CVD and sintering.

Uniform Heat Distribution

Achieving uniform heating across the entire quartz

tube is a critical factor in many applications, especially in CVD and thin-film

deposition processes. Brother Furnace ensures that their quartz tube furnaces

provide uniform heat distribution by using advanced heating elements, such as

molybdenum disilicide (MoSi2) or silicon carbide (SiC), and efficient design to

minimize hot spots.

Customizable Configurations

Recognizing the diverse needs of its customers, Brother Furnace offers customizable configurations for their quartz tube furnaces. Users can select tube sizes, heating zones, and temperature ranges based on the specific requirements of their application. The modular design allows for flexibility, ensuring that the furnace can adapt to various sample sizes and process parameters.

High Purity and Inert Environment

The quartz tube is not only thermally stable but also chemically inert, making it an excellent choice for processes that require a contamination-free environment. This feature is particularly valuable in CVD and other chemical processing applications where the integrity of the material being processed must be maintained.

Safety and Efficiency Features

Brother Furnace’s quartz tube furnaces come equipped with multiple safety features, including over-temperature protection, thermal insulation, and a user-friendly control interface. These safety mechanisms are essential for preventing accidents in high-temperature environments. Additionally, the furnaces are designed with energy efficiency in mind, minimizing power consumption while maintaining high heating performance.

Applications of Quartz Tube Furnaces

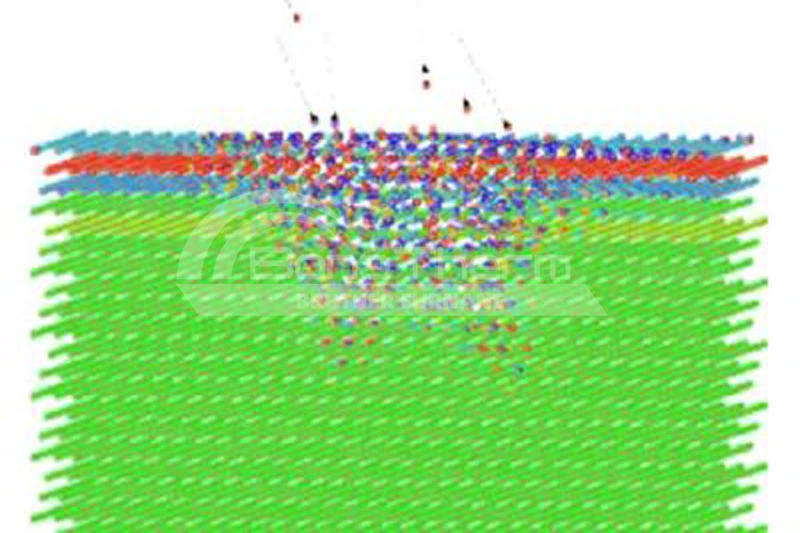

Chemical Vapor Deposition (CVD) Chemical Vapor Deposition (CVD) is one of the

most important applications of quartz tube furnaces. In this process, a chemical

reaction occurs inside the quartz tube, which causes a material to be deposited

onto a substrate.

This process is used extensively in the semiconductor industry for the fabrication of integrated circuits, thin-film solar cells, and optical coatings. Brother Furnace’s quartz tube furnaces offer the high temperatures, uniform heating, and controlled atmosphere necessary for precise and efficient CVD processes.

Sintering and Annealing

Sintering is a heat treatment process used to bond particles of a material by applying heat without melting the material completely. Annealing is a process used to relieve internal stresses and improve the material's properties. Both processes require precise temperature control and uniform heating to achieve the desired material properties. The quartz tube furnaces provide the necessary thermal conditions for effective sintering and annealing of advanced materials, including ceramics, metals, and composites.

Material Synthesis

For the synthesis of advanced materials, such as high-performance ceramics and composite materials, the controlled application of heat is essential to achieve the desired chemical structure and properties. Brother Furnace’s quartz tube furnaces support a variety of material synthesis processes by providing high temperatures in a controlled environment, ensuring optimal results for both research and industrial-scale production.

Graphene and Nanomaterials Production

The production of advanced

nanomaterials, including graphene, requires specialized equipment capable of

maintaining high temperatures while ensuring the purity of the material. The quartz tube furnaces are ideal for the synthesis of graphene and other

nanomaterials due to their high-temperature stability, purity, and flexibility

in process control.

Heat Treatment for Semiconductor Materials

The semiconductor industry demands exceptional precision when it comes to heat treatment. Brother Furnace’s quartz tube furnaces are used in semiconductor fabrication processes such as doping, diffusion, and oxidation. These processes require the furnace to maintain a uniform temperature profile and controlled atmosphere, both of which Brother Furnace’s systems excel at.

Why Choose Brother Furnace's Quartz Tube Furnaces?

Precision Engineering

Brother Furnace has a long-standing reputation for producing high-quality, precision-engineered heat treatment equipment. Their quartz tube furnaces reflect this commitment to excellence, with meticulous attention to detail in every component. The result is a furnace that provides superior performance, reliability, and consistency.

Customer-Centric Design

One of the key advantages of Brother Furnace’s quartz tube furnaces is their

customer-centric design. These furnaces can be customized to meet the specific

needs of each customer, ensuring that the equipment delivers optimal performance

for their application. Whether it's a small-scale laboratory experiment or

large-scale industrial production, Brother Furnace can tailor the furnace to

meet the exact specifications.

Industry-Leading Support

In addition to offering high-performance furnaces, Brother Furnace also provides industry-leading customer support. From initial consultation to installation and post-purchase service, Brother Furnace ensures that their customers have the resources and expertise they need to make the most of their quartz tube furnaces.

Innovative Technology

As a forward-thinking manufacturer, Brother Furnace continually innovates to ensure their products stay at the cutting edge of technology. Their quartz tube furnaces are equipped with the latest advancements in heating technology, temperature control systems, and energy-efficient design.

Conclusion

In today’s fast-paced and technology-driven industries, Brother Furnace’s

quartz tube furnaces are proving to be an indispensable tool in a wide range of

advanced applications. With their ability to provide high-temperature precision,

uniform heating, and flexible configurations, these furnaces help industries

like semiconductor manufacturing, material science, and nanotechnology achieve

consistent, high-quality results.

The technical excellence, safety features, and energy efficiency built into Brother Furnace’s quartz tube furnaces make them an investment that pays dividends in both performance and reliability. Whether for research, industrial production, or material development, Brother Furnace is the trusted name for precision heating in a variety of advanced applications.

If you are interested in the tube furnace of Brother Furnace, welcome to contact us. Brother Furnace is always ready to serve you.