What is a Sliding Tube Furnace? 4 Details to Help You Understand Quickly

Sliding tube furnace is a kind of laboratory equipment, which realizes the

rapid heating and cooling of samples through the sliding of the furnace on the

tube, and is widely used in ceramics, metallurgy, electronics, glass, chemical

industry, machinery, and other fields of material treatment, powder roasting,

ceramic sintering, high-temperature experiments, and CVD experiments.

As an advanced heat treatment equipment, the unique design and superior performance of sliding tube furnaces make it the first choice of many scientific research institutions and industrial enterprises. At the forefront of scientific research, especially in the fields of material science, chemical synthesis, and biotechnology, its role is irreplaceable.

As a professional manufacturer of sliding tube furnaces, Brother Furnace will

discuss the basic concepts of sliding tube furnaces, its core advantages, and

its wide range of applications in this article to help you better understand the

value of this sliding tube furnace.

1. Basic Concept of Sliding Tube Furnace

What is a Sliding Tube Furnace?

A sliding tube furnace is a kind of equipment used for high-temperature heat treatment. Its main feature is that the furnace is in the form of a tube, which is usually made of a high-purity quartz tube.

This tube furnace heats the sample inside the tube using a resistance wire, allowing it to be heated and treated in a controlled temperature environment. The sliding tube furnace gets its name from a key feature in its design - the furnace can be moved from side to side to process materials in different temperature zones. This design gives the sliding tube furnace greater flexibility and efficiency in processing samples.

Working Principle of the Sliding Tube Furnace

The core operating principle of the sliding tube furnace is based on resistance heating and atmosphere control. The resistance heating system consists of a series of resistance wires, through which an electric current is passed, generating heat that heats the furnace tube and the sample inside.

The temperature of the furnace tube can be precisely adjusted by the control

system to achieve the desired experimental conditions. In addition, the sliding

tube furnace can be adjusted to control the reaction environment of the sample

by adjusting the atmosphere, such as oxidizing, reducing, or inert atmosphere,

to meet different experimental needs.

2. Core Advantages of Sliding Tube Furnaces

Excellent Performance and Precise Temperature Control

Sliding tube furnaces are capable of stable operation at temperatures up to 1200°C, which is critical for many experiments requiring high-temperature treatment. Brother Furnace's sliding tube furnaces utilize high-purity quartz tubes as the furnace tubes, which, together with the HRE resistance wire heating system, ensures uniform heating and efficient heat transfer in the furnace.

Its intelligent 50-segment programmable automatic control system allows customers to set up complex heating programs according to experimental needs, realizing high-precision temperature control. This high-precision temperature control system not only improves the repeatability of experiments but also reduces errors due to temperature fluctuations.

Safe and Reliable Design

The safety of the slide heating tube furnace is a top priority in the design of Brother Furnace. Brother Furnace has equipped the tube furnace with an over-temperature protection function. When the temperature in the tube exceeds the set value, the system will automatically cut off the power to prevent overheating.

In addition, the furnace is carefully designed to ensure stable performance and safety during long-term use. Brother Furnace also conducts rigorous quality tests on the equipment to ensure that it operates safely and reliably under all operating conditions.

Versatile Applications

The versatility of the sliding tube furnace allows it to excel in a variety of applications in different fields. For example, in the field of materials science, it is used for experiments such as the growth of graphene, high-temperature atmosphere sintering, and atmosphere reduction.

In chemical research, the sliding tube furnace is capable of performing

chemical vapor deposition experiments to support the study of various chemical

reactions. In industrial applications, it can be used for vacuum annealing and

other high-temperature treatment processes. The wide applicability of sliding

tube furnaces makes them ideal for researchers and engineers.

Automatic Slide System

The fast cooling tube furnace is equipped with motorized slides (1200 mm length as standard). This design allows the furnace to move automatically from side to side during operation without manual intervention. This automated feature not only simplifies the operation process but also realizes the ability of the furnace to cool down quickly, which meets the stringent requirements of materials that are subjected to sudden cooling and heating during experiments.

Through the motorized slide system, the experimenter can effectively avoid the risk of direct operation, improving the safety and efficiency of the experiment.

Superior Heat Preservation

The design of the sliding tube furnace focuses on the insulation effect and temperature uniformity of the furnace chamber. The use of high-purity quartz tubes ensures good insulation of the furnace and reduces heat loss.

Temperature uniformity in the tube is ensured by the precise heating system and the optimized design of the furnace, which allows for uniform heating of the samples during processing. This superior insulation and temperature uniformity is essential to ensure accurate and reproducible experiments.

3. Application Areas of Sliding Tube Furnaces

Material Science

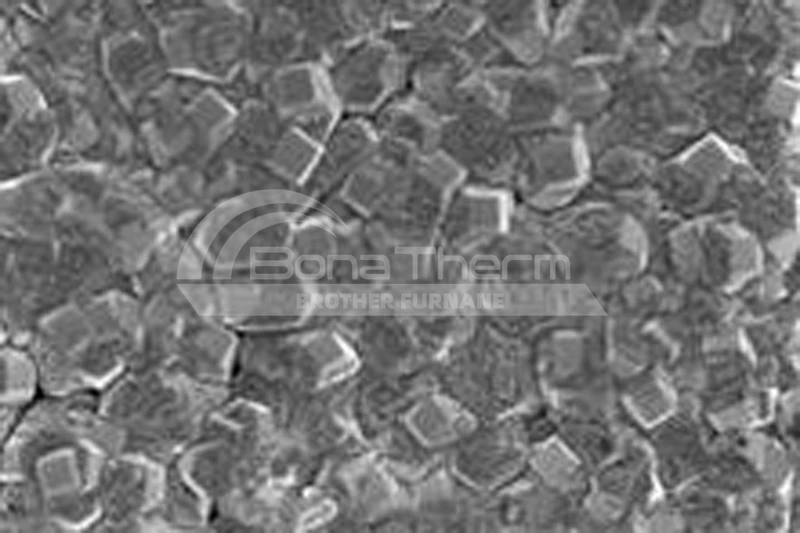

In the field of materials science, the sliding tube furnace is often used to study the synthesis and performance testing of new materials. For example, it can be used for experiments on the growth of graphene, which, as a material with excellent electrical conductivity, is widely used in the fields of electronic devices and energy storage.

The high-temperature performance and precise temperature control capability

of the sliding tube furnace make it ideal for graphene synthesis. In addition,

it can also be used for high-temperature sintering and atmosphere reduction

experiments of other materials.

temperature control capability

of the sliding tube furnace make it ideal for graphene synthesis. In addition,

it can also be used for high-temperature sintering and atmosphere reduction

experiments of other materials.

Chemical Synthesis

Sliding heated tube furnaces play an important role in chemical synthesis. Especially in chemical vapor deposition experiments, sliding tube furnaces provide a stable high-temperature environment, allowing chemical reactions to take place under precisely controlled conditions. By adjusting the atmosphere inside the furnace tube, researchers can achieve precise control of the chemical reaction to obtain the desired chemical product or material.

Biotechnology

In the field of biotechnology, the fast cooling tube furnace also has a wide range of applications. For example, it can be used for high-temperature treatment and annealing processes of biological materials to improve their properties or change their physical properties. The high-temperature performance and precise temperature control of sliding tube furnaces make the process more controllable, thus helping researchers to obtain more accurate experimental results.

Industrial Applications

In industrial applications, the sliding tube furnace is commonly used for

vacuum annealing and other high-temperature treatment processes. It is capable

of high-temperature treatment under vacuum or in a specific atmosphere,

effectively removing impurities from materials and improving their quality and

properties. The versatility and high-temperature performance of the sliding tube

furnace makes it an important piece of in industrial production.

4. Brother Furnace: Your Reliable Sliding Tube Furnace Manufacturer

As a leading manufacturer of sliding tube furnaces, Brother Furnace's electric furnaces offer a range of unique advantages designed to meet your needs in research and industrial applications. Not only do Brother Furnace's sliding tube furnaces lead the way in design and functionality, they also demonstrate significant advantages in the following areas:

High-quality Materials and Processes

The vacuum sliding tube furnace utilizes high-purity quartz tubes and advanced resistance wire heating technology to ensure the high-temperature performance and long-term stability of the equipment. Brother Furnace also strictly controls the selection of materials and the implementation of processes during the production process to ensure that each piece of equipment meets the highest quality standards.

Advanced Temperature Control System

The sliding tube furnace is equipped with an intelligent 50-segment programmable automatic control system, which allows you to easily set the temperature program according to your experimental needs. The system not only supports complex heating curves but also has an over-temperature protection function to ensure the safety and reliability of the experimental process.

All-round Customer Service

Brother Furnace is committed to providing customers with a full range of support services, including equipment installation, commissioning, and technical training. Brother Furnace's professional team will provide personalized solutions according to your specific needs, to ensure that your equipment can operate in the best condition.

Customized Solutions

According to the needs of different customers, Brother Furnace also provides customized sliding tube furnace solutions to meet specific experimental requirements or industrial applications. Brother Furnace's technical team will work closely with you to design and manufacture the equipment that meets your needs.

Brother Furnace Looks Forward to Working with You!

As an advanced heat treatment equipment, the importance of sliding tube furnaces in research and industrial applications cannot be overstated. Vacuum

sliding tube furnaces from Brother Furnace have become the equipment of choice

for many researchers and engineers due to their high-temperature performance,

precise temperature control, safe and reliable design, and wide range of

applications.

Through this article, Brother Furnace hopes you have gained a better understanding of sliding tube furnaces.

If you are looking for heat treatment equipment with excellent performance and comprehensive functions, Brother Furnace's sliding tube furnace is undoubtedly your ideal choice.

Welcome to contact us to learn more about our sliding tube furnaces. Brother Furnace will provide the most professional solution for your research and production.