Why Choose the Horizontal Vacuum Tube Furnace?

In modern industries where precision and consistency are paramount, the

horizontal vacuum tube furnace has become a critical tool in manufacturing and

research.

Known for its unique design that allows for exact temperature control and the capability to operate in vacuum or inert gas environments, the horizontal vacuum tube furnace offers advantages over traditional furnaces that simply cannot be ignored.

These furnaces are essential across sectors like semiconductor manufacturing, materials science, aerospace, and many others where temperature-sensitive processes demand stability and uniformity. The use of a vacuum tube furnace can significantly enhance quality, improve production efficiency, and reduce costs by minimizing oxidation and contamination.

In this article, Brother Furnace will explore the fundamentals of horizontal

vacuum tube furnaces, their main features, industry applications, and trends

shaping the future of this innovative technology.

Understanding Horizontal Vacuum Tube Furnaces

The horizontal vacuum tube furnace is a specialized high-temperature furnace designed for precise thermal processing within a controlled environment.

Unlike traditional thermal processing ovens, which operate in ambient atmospheric conditions, vacuum tube furnaces create a vacuum environment or utilize specific gases like nitrogen and argon for inert atmosphere processing.

This ability to operate in a vacuum or under protective atmospheres is particularly valuable for industries where materials are sensitive to oxidation or require precise thermal cycling.

Key Features and Benefits

Precise Temperature Control

One of the standout features of a horizontal tube furnace is its precise temperature control capabilities, which are crucial for high-quality output in temperature-sensitive processes.

With advanced control systems, these furnaces can maintain specific

temperatures across the heating zones, allowing users to create customized

temperature profiles for materials that require careful thermal management. This

feature is essential for processes like sintering and brazing, where even minor

temperature variations can affect the final product’s quality.

Uniform Heating Capabilities

Horizontal vacuum tube furnaces are designed for uniform heating, critical in applications such as annealing and tempering, where consistency is key. The heating furnace feature allows for an even distribution of heat along the furnace's length, ensuring each section of the material receives consistent treatment.

This uniformity is particularly valuable in the production of high-performance materials used in industries like aerospace and semiconductor manufacturing.

Vacuum and Controlled Atmosphere Processing

A distinctive capability of a vacuum tube furnace is its ability to operate in a vacuum or under a controlled atmosphere, such as argon or nitrogen. This inert atmosphere furnace capability prevents oxidation and is essential for applications in which materials are sensitive to air exposure, such as advanced ceramics, metals, and alloys. By maintaining a vacuum or inert environment, horizontal vacuum tube furnaces can help ensure the integrity and purity of the processed materials.

Energy Efficiency

Compared to traditional furnaces, horizontal vacuum tube furnaces are energy

efficient. Their construction minimizes heat loss, resulting in cost savings,

especially in industries requiring continuous operation furnaces. Their design

and construction also allow for faster heating and cooling cycles, which

contributes to overall efficiency by reducing the time needed for thermal

processing.

Versatility in Material Processing

From materials testing to gas processing, the versatility of the horizontal vacuum tube furnace is one of its greatest strengths. It can be adapted to work with various materials and thermal processes, making it suitable for diverse applications across industries.

Whether it’s conducting tests in a materials testing furnace or working with gases in a gas processing furnace, the flexibility offered by these furnaces means that they can handle multiple processes, making them a smart investment for labs and production facilities.

Applications Across Industries

Materials Science and Research

In materials science, the vacuum tube furnace is indispensable for research focused on developing new materials and investigating the properties of existing ones. The precise temperature control and controlled environment enable scientists to study materials under highly specific conditions, facilitating advancements in fields such as nanotechnology, composites, and polymers.

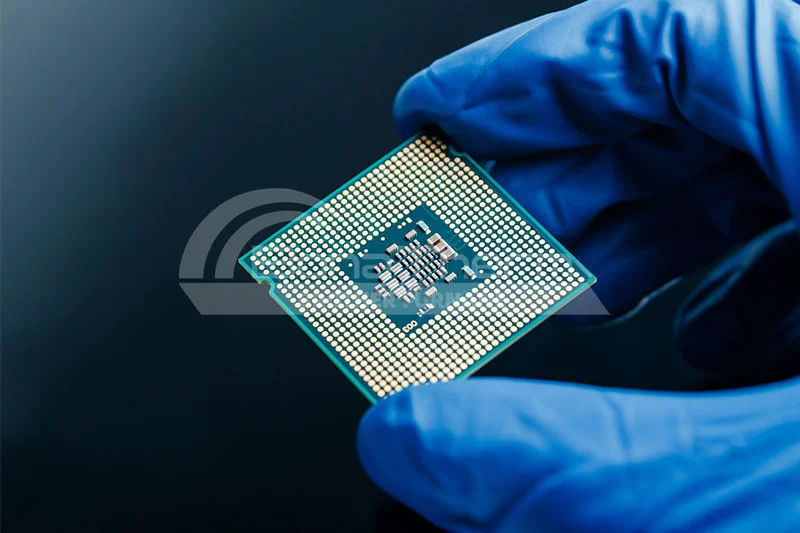

Semiconductor Manufacturing

In semiconductor manufacturing, purity, and precision are non-negotiable, and

the horizontal vacuum tube furnace plays a pivotal role in meeting these

requirements. It allows manufacturers to process wafers and other components in

an oxidation-free environment, significantly reducing contamination and

improving the overall product yield.

Additionally, the uniform heating capacity of these furnaces helps maintain the consistency required in semiconductor products, where even minor inconsistencies can lead to costly errors.

Aerospace and Automotive Industries

For the aerospace and automotive sectors, horizontal vacuum tube furnaces are essential for processing components that must withstand extreme conditions. These industries rely on vacuum furnaces for annealing and tempering, as well as for gas processing, to improve parts' durability and strength.

Medical Device Production

The medical device industry relies on vacuum tube furnaces for producing biocompatible materials and components used in implants and instruments. For instance, annealing processes ensure that metals are less brittle, a critical requirement in devices that must perform reliably inside the human body. A horizontal vacuum tube furnace offers the controlled conditions necessary to meet the stringent standards of medical manufacturing.

Choosing the Right Horizontal Vacuum Tube Furnace

Selecting the right horizontal vacuum tube furnace depends on several factors, including:

Size and Temperature Range: The dimensions and temperature capabilities

should align with the intended application.

Atmosphere Control: Determine if the process requires vacuum or specific gas atmospheres, as this will influence the type of furnace selected.

Customization Options: Many manufacturers, such as Brother Furnace, offer customizable high-performance tube furnaces to meet specific requirements, from unique dimensions to advanced temperature control systems.

Integration with Existing Systems: Choose a furnace that seamlessly integrates with your existing production line for an efficient setup.

Brother Furnace’s expertise in producing custom tube furnaces ensures that each furnace is designed to meet the rigorous demands of your industry, optimizing both productivity and product quality.

Conclusion

The horizontal vacuum tube furnace represents a significant advancement in thermal processing technology, with unmatched capabilities in temperature control, uniform heating, and atmosphere management.

It is an invaluable asset in any industry where high-quality, consistent processing is crucial, providing a competitive edge by improving efficiency, reducing contamination, and enhancing overall product quality.

Brother Furnace offers an extensive range of horizontal vacuum tube furnaces

that cater to the specific needs of modern industries.

For industries looking to elevate their production processes, Brother Furnace provides expert consultation on selecting and customizing horizontal vacuum tube furnaces to meet diverse application needs.

If you want to know more details, please feel free to contact us.