A Precision Materials Company in Geneva Orders a Box Type Resistance Furnace

In the picturesque city of Geneva, where innovation in advanced materials and

precision engineering thrives, a well-established precision materials company

has taken a significant step forward by investing in a box-type resistance furnace from Brother Furnace.

Known for their meticulous work with high-performance metals, magnetic materials, and electronic components, this Geneva-based company needed a furnace that could reliably handle demanding heat treatment tasks while providing exceptional temperature control precision and uniform temperature distribution.

This collaboration marks yet another achievement in Brother Furnace's journey to offer top-tier heating solutions, aligning with the client’s high standards for quality and precision.

As a professional manufacturer, Brother Furnace is committed to creating

custom solutions that not only meet but exceed industry requirements,

positioning our products as essential tools for clients who value durability,

precision, and efficiency in their heat treatment equipment.

Client Background: Meeting the Needs of a Precision-Focused Industry

The Geneva-based company is a leading name in precision materials, with a long history of catering to industries that require high accuracy and reliability.

Their core operations involve tasks such as chemical analysis, sintering of materials, small steel part heating, and electronic component pre-burning. Each of these processes demands equipment that offers stability, consistency, and safety — qualities essential in a thermal treatment furnace.

However, their previous furnace equipment struggled to keep up with the rising demands of their operations, particularly as they expanded into new areas such as magnetic material processing.

As their production needs grew, the company sought an upgraded box-type resistance furnace that could ensure uniform heating for their complex processes. They were particularly interested in a solution that could cater to various heat treatment applications within a single unit, including laboratory and industrial requirements.

Following extensive market research, they identified Brother Furnace as a trusted provider known for its high-temperature box furnace and refractory brick muffle furnace solutions.

The company was attracted not only by our reputation but also by our flexibility in providing custom resistance furnace solutions tailored to specific client requirements.

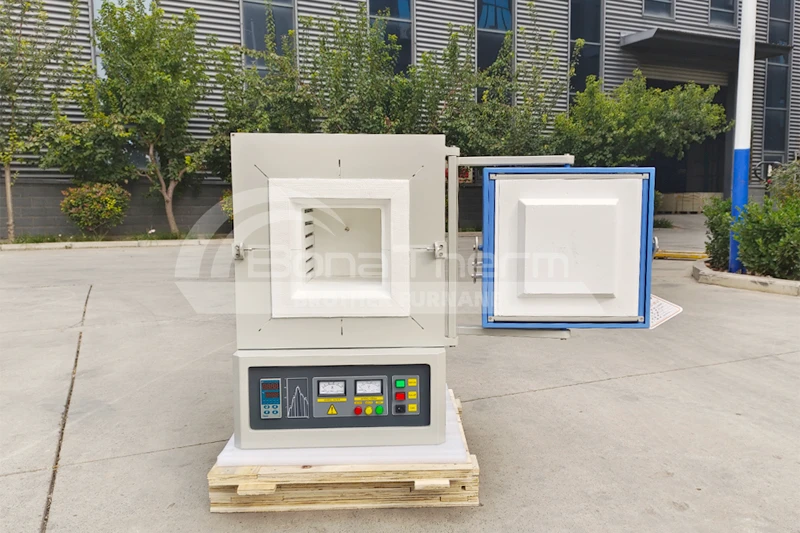

Brother Furnace’s Box Type Resistance Furnace

Brother Furnace is dedicated to designing and manufacturing box-type resistance furnaces that deliver unparalleled performance in demanding

environments.

For this client, we recommended our advanced high-temperature box furnace model, specifically engineered to provide temperature control precision and optimal safety.

Refractory Brick Muffle Design: Constructed with durable refractory brick muffle linings, the furnace is designed to endure high temperatures and provide exceptional heat retention. This feature is especially beneficial for applications that require prolonged exposure to high heat, as it ensures the longevity of the furnace’s components and reduces overall energy consumption.

Uniform Temperature Distribution: One of the most critical aspects of this furnace is its ability to maintain uniform temperature distribution throughout the chamber. This feature is essential for the client’s tasks involving magnetic material processing and electronic component pre-burning, where uneven temperatures could lead to compromised product quality.

Temperature Control Precision: Equipped with high-precision controllers and advanced thermocouples, Brother Furnace’s box-type resistance furnace allows operators to achieve precise furnace temperature calibration. This level of control is invaluable for sensitive processes like chemical analysis and sintering furnace applications, where even slight temperature fluctuations can alter material properties.

Energy Efficiency and Durability: Designed with energy-efficient elements,

this furnace reduces operational costs while ensuring powerful heating

capabilities. The integration of top-quality materials ensures that the furnace

operates reliably even after extended use, which is vital for a high-demand

operation.

Customization and Installation

To meet the specific needs of the Geneva company, Brother Furnace provided additional customization options.

Our engineers worked closely with the client to modify the box-type resistance furnace in ways that optimized its performance for their unique applications. Customizations included adjustments to the furnace’s control settings, enhanced insulation for prolonged high-temperature use, and additional safety features to meet regulatory standards.

Our team also conducted a thorough training program for the client’s staff, covering operational procedures, maintenance tips, and best practices for furnace temperature calibration. This hands-on training allowed the company’s team to integrate the furnace effectively into their existing processes and maximize its benefits from day one.

Broader Impact on the Client’s Operations

With the integration of Brother Furnace’s box-type resistance furnace, the Geneva-based company has been able to enhance both the efficiency and quality of its heat treatment processes. The addition of this furnace has reduced downtime and increased productivity, allowing the company to take on more ambitious projects without sacrificing precision.

Furthermore, the furnace’s robust construction and advanced temperature

control systems have helped it maintain a competitive edge in the precision

materials industry, reinforcing its reputation as a trusted supplier in their

field.

Why Brother Furnace is the Preferred Choice for Box Type Resistance Furnaces

Brother Furnace’s commitment to innovation and quality has established us as a preferred manufacturer of industrial heating equipment.

Our custom resistance furnace solutions are designed with the understanding that each client’s needs are unique, especially in fields that demand precision and reliability. With a product line that includes box-type resistance furnaces, refractory brick muffle furnaces, and high-temperature box furnaces, Brother Furnace provides solutions that offer consistent performance and durability.

Our products are crafted to support industries that require unwavering quality and performance, enabling our clients to pursue excellence in their respective fields.

Precision and Reliability with Brother Furnace

In conclusion, the Geneva-based company’s decision to invest in Brother Furnace’s box-type resistance furnace has proven transformative for its

operations, elevating its capabilities in both research and production.

This case study demonstrates not only the furnace’s ability to meet the most rigorous standards but also Brother Furnace’s dedication to delivering products that support industry leaders in achieving their goals.

Brother Furnace takes pride in providing industrial heating equipment that combines technical innovation with exceptional durability. Our box-type resistance furnace continues to set new standards for temperature control precision and uniform temperature distribution, serving applications as diverse as laboratory muffle furnace tasks and magnetic material processing.

For industries seeking reliable, efficient, and customizable heat treatment solutions, Brother Furnace remains the ideal partner, committed to supporting every client’s pursuit of precision, safety, and excellence.