A Ukrainian Precision Machining Company Purchases a Muffle Furnace from Brother Furnace

In modern industrial production, heat treatment equipment plays a vital role

in material processing and manufacturing. Whether it's aerospace, automotive

manufacturing, or the medical device industry, they all rely on high-precision

heat-treating equipment to ensure product excellence in quality and

performance.

As the world's leading manufacturer of muffle furnaces, Brother Furnace has earned widespread market recognition for its expertise, quality products, and excellent service.

Recently, a Ukrainian precision machining company chose Brother Furnace's muffle furnaces to bring unprecedented efficiency improvement and product quality assurance to its production line.

Customer Background: Ukrainian Precision Machining Company with High Standards

This Ukraine-based precision machining company, which was founded in the

1990s, has quickly made a name for itself in the international marketplace

through technical excellence and strict quality control. The company primarily serves the aerospace, automotive manufacturing, and

medical device sectors, providing high-quality mechanical components and

precision machining services to these highly sophisticated industries.

In these fields, any small error can lead to a significant drop in product performance, so customers are particularly careful in their choice of production equipment, especially in processes involving heat treatment. In the past few years, this company had been using traditional heat treatment equipment, and although it was able to meet the basic production requirements, it gradually realized the limitations of the existing equipment as market competition intensified and customer requirements continued to rise.

For example, the traditional equipment did not perform adequately in terms of temperature control accuracy, energy management, and productivity, which led to certain scrap rates and energy consumption problems during processing. Therefore, they decided to look for equipment that could comprehensively enhance the heat treatment process to meet the increasingly demanding market needs.

After detailed market research and technical evaluation, this company finally

chose Brother Furnace's muffle furnace. During the evaluation process, they not only examined the technical

parameters and performance of Brother Furnace's products but also paid special

attention to the stability, ease of operation, and quality of after-sales

service.

In the end, Brother Furnace won the customer's trust with its excellent product quality and professional technical support and became their preferred supplier of heat treatment equipment.

Why Brother Furnace Can Beat the Competitors

Brother Furnace's chamber furnaces are the ideal choice for many precision machining organizations because of the high standards and demands placed on them during design and manufacture. The chamber furnace not only improves productivity but also helps customers achieve remarkable results in practical applications:

Excellent Temperature Control Precision

Precise temperature control is essential in the heat treatment process. Brother Furnace's muffle furnaces are equipped with an advanced temperature control system that enables precise temperature control precision.

The high accuracy of the temperature control system ensures that workpieces are treated uniformly throughout the process, avoiding quality problems caused by temperature fluctuations, and is particularly suitable for the aerospace and medical device industries, where heat treatment is extremely demanding.

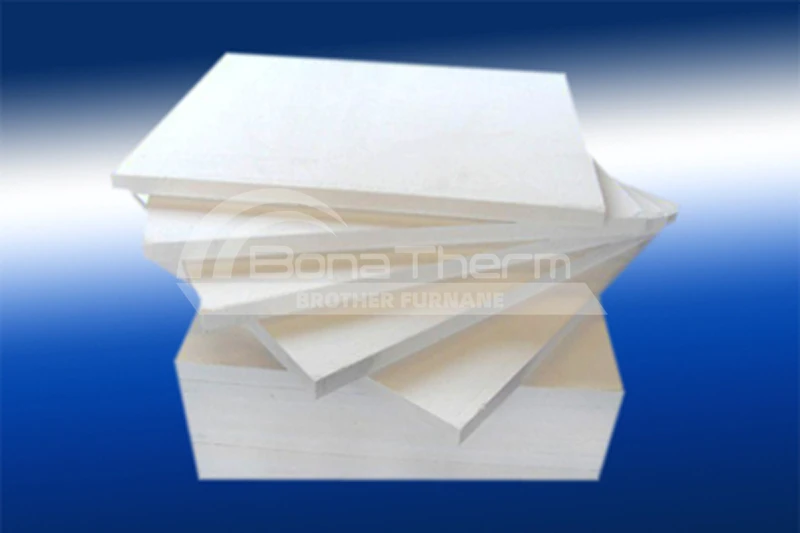

Highly Durable Furnace Chamber Materials

To ensure long-term stable operation in high-temperature environments,

Brother Furnace uses highly wear-resistant polycrystalline mullite fiber in the

muffle furnace chamber.

This material not only has excellent thermal insulation properties, but also effectively resists the effects of high temperatures and chemical corrosion, thus extending the service life of the equipment, reducing the frequency of maintenance and replacement, and saving operating costs for customers.

Intelligent Operating System

The intelligent control system of the chamber furnace makes the operation easier and more intuitive. Customers can easily set and adjust the parameters through the touch screen and can monitor the temperature profile and treatment process in real time.

Customer Experience: Atmosphere Sintering Furnace Performs Excellently

During the installation and commissioning of the equipment, Brother Furnace's professional team worked closely with the Ukrainian customer's engineers to ensure a smooth start-up. The customer highly appreciated Brother Furnace's quick response and the professionalism of the technical support team.

After the equipment was officially put into production, the customer found that Brother Furnace's muffle furnace exceeded their expectations in terms of precision and consistency of temperature control.

This not only greatly improves the processing quality of parts, but also

effectively reduces the scrap rate caused by temperature instability.

In addition, the customer particularly mentioned the ease of operation of the equipment and the intelligent control system’s effect on productivity. In the past, their operators had to spend a lot of time manually monitoring and adjusting the temperature, but now, with Brother Furnace's intelligent system, the entire heat treatment process has become more automated and controllable. This change not only reduces labor costs but also avoids quality risks due to operational errors.

Another aspect that satisfied the customer was the energy-saving effect of the equipment. Compared with the equipment they were using before, the muffle furnace has a significant reduction in energy consumption. Compared to the past, their energy costs have been reduced by almost 15 percent, which is undoubtedly a huge advantage in the current context of rising energy prices.

With this successful cooperation, Brother Furnace has once again proved its strength and expertise as the world's leading muffle furnace manufacturer.

The high level of satisfaction of the Ukrainian customers with muffle furnaces is not only due to the excellent performance of the equipment itself but also to Brother Furnace's all-round support from product design, and manufacturing to after-sales service.

Brother Furnace - Your Reliable Muffle Furnace Manufacturer

In the future, Brother Furnace will continue to put the "customer first" and

strive to provide even better heat treatment equipment and solutions to our

customers around the world.

Whether it is for aerospace, automotive manufacturing, or other industries with high heat treatment requirements, Brother Furnace will consistently provide customers with the most advanced and reliable muffle furnace to help customers succeed in the highly competitive marketplace.

Brother Furnace is not only an equipment supplier, but also your long-term partner in the field of industrial heat treatment. No matter what kind of heat treatment challenges you face, Brother Furnace will guarantee your business with professional technology, rich experience, and high-quality service.