Choose the Horizontal Tube Furnace or Vertical Tube Furnace

As an important heat treatment equipment, tube furnaces are now widely used

in many fields such as material synthesis, chemical reaction, and heat

treatment. With the increasing market demand for efficient and reliable

equipment, as a professional tube furnace manufacturer, Brother Furnace is

committed to providing high-performance tube furnaces and tube furnaces.

Choosing the right tube furnace not only concerns the efficiency of experiment and production but also directly affects the quality of the final product.

Therefore, this article will provide you with detailed information on how to choose between these two types of tube furnaces, which will help you find the most suitable solution for your needs among these two types of tube furnaces.

|  |

Overview of Horizontal and Vertical Tube Furnaces

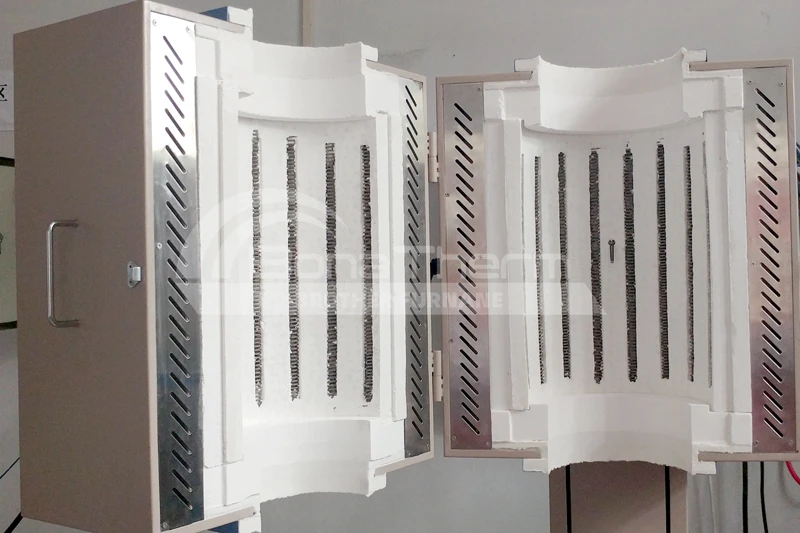

Features of Horizontal Tube Furnaces

Horizontal tube furnaces are designed so that the furnace tubes are placed horizontally, and are typically used for processes that require larger throughputs. Their main features include:

Uniform heating: The horizontal arrangement helps to distribute the heat evenly and is suitable for the treatment of a wide range of substances. Through the rational design of the heating system, precise control of the temperature inside the furnace can be realized, ensuring that the material is subjected to uniform temperature distribution throughout the heating process.

Easy to operate: The design of the tube furnace makes it easier to load and remove materials, reducing operating time. Operators can process batches more easily, which can significantly improve efficiency, especially in mass production.

Adaptable: A wide range of material types can be processed, especially

granular or powdered materials. Whether for chemical synthesis, metal melting,

or heat treatment of materials, horizontal tube furnaces offer reliable

solutions.

Features of Vertical Tube Furnaces

Vertical tube furnaces are suitable for handling high temperatures or for applications that require rapid temperature rise.

High space utilization: The vertical tube furnace is designed to save floor space and is suitable for laboratories or plants with limited space. For many laboratories, the ability to work efficiently in a small space is critical.

Excellent high-temperature performance: The ability to work stably at higher temperatures makes it suitable for high-temperature synthesis reactions. The synthesis and processing of many advanced materials require high temperatures, and the vertical tube furnace is designed to effectively address this need.

Prevents material deposition: Vertical construction helps prevent the

deposition of powdered or granular materials and ensures material flow. When

processing powders or poorly flowing materials, the vertical design can

effectively avoid clogging and sedimentation problems, and improve work

efficiency.

Key Factors in Selecting a Tube Furnace

When choosing between a horizontal and vertical tube furnace, there are several factors to consider to ensure that the equipment selected best meets your process needs.

1. Field of Application

First of all, determining your application area is an important step in selecting a tube furnace. Different applications have different requirements for tube furnaces. For example:

Material synthesis: If your work mainly involves the synthesis of materials, especially granular or powdered materials, a horizontal tube furnace may be more suitable. Their large handling capacity and uniform heating characteristics make the material synthesis process more efficient.

Chemical reactions: If your process involves chemical reactions, especially

at high temperatures, a vertical tube furnace may be more advantageous. Their

high-temperature performance and fast ramp rates can meet the stringent

temperature and time requirements of chemical reactions.

2. Temperature Range

Temperature range is a key factor when selecting a tube furnace. Different tube furnaces are designed to withstand different temperature ranges, so you need to choose the right equipment for your experimental requirements.

High-temperature processing: If your experiments need to be carried out at temperatures higher than 1000°C, vertical tube furnaces usually offer better high-temperature stability and performance.

Low-temperature processing: For some low-temperature synthesis or heat treatment processes, a horizontal tube furnace may be a better choice, especially when larger volumes of material are required.

Application Scenarios for Horizontal and Vertical Tube Furnaces

Materials Science

In materials science research, horizontal tube furnaces are commonly used to

synthesize new materials such as ceramics and alloys. Through uniform heating,

researchers can precisely control the synthesis process to ensure the

homogeneity and properties of the materials.

Semiconductor Industry

In semiconductor manufacturing, vertical tube furnaces are widely used in thin film growth and doping processes. Their high-temperature performance and precise control ensure film uniformity and high material purity.

Chemical Synthesis

For chemical synthesis, horizontal tube furnaces can handle large batches of raw materials while ensuring uniformity and stability of the reaction. Vertical tube furnaces are suitable for synthesis processes that require rapid ramp-up and high-temperature reactions.

Heat Treatment of Materials

In the heat treatment of materials, horizontal tube furnaces are often used for annealing and quenching of metals and ceramics due to their ease of operation. Vertical tube furnaces, on the other hand, are suitable for some high-temperature heat treatment applications and can provide higher temperatures and faster heat-up rates.

Advice on Tube Furnace Selection and Purchase

When selecting and purchasing a tube furnace, in addition to the technical factors mentioned above, you should also consider the following aspects:

1. Manufacturer's Reputation

It is crucial to choose a reputable manufacturer. A professional manufacturer

not only provides high-quality products but also guarantees after-sales service

and technical support. Brother Furnace has accumulated rich experience in the

field of tube furnace manufacturing and is committed to providing customers with

the best product solutions.

2. After-sales Service

After-sales service is an important factor to ensure the normal operation of the equipment. When choosing a tube furnace, it is essential to understand the manufacturer's after-sales service policy, including warranty, maintenance, and technical support.

3. Customized Requirements

If you have special requirements for your experiments or production, choosing a manufacturer that can provide customized services will be more helpful in meeting your needs. The team at Brother Furnace is able to provide customized tube furnace solutions based on the specific needs of our customers, ensuring optimal performance of the equipment.

Brother Furnace: Specialized Tube Furnace Manufacturer

When choosing between horizontal tube furnaces and vertical tube furnaces, it is crucial to

consider several factors, including area of application, temperature range,

heating method, material compatibility, and throughput.

By analyzing these factors in-depth, you will be able to find the tube furnace that best suits your needs, ensuring that your experiments and production run efficiently.

As a professional tube furnace manufacturer, Brother Furnace is committed to providing customers with high-performance and highly reliable tube furnaces. Whether you are a laboratory researcher or an industrial manufacturer, we have the right solution for you.

Please feel free to contact us. Brother Furnace will provide you with professional products and attentive service.