Graphene Chemical Vapor Deposition Furnace: Revolutionizing the Future of Graphene Production

Graphene is a material that has transformed industries with its exceptional

properties, providing innovations in fields ranging from electronics to energy

storage and even medicine.

Known for its impressive conductivity, flexibility, and strength, graphene offers vast potential for technological advancements, spurring demand for effective and high-quality graphene production methods.

Among the most efficient approaches for producing high-quality graphene, graphene chemical vapor deposition furnaces (CVD furnaces) stand out. These advanced furnaces from Brother Furnace, designed to ensure contamination-free graphene production, are vital in synthesizing graphene for industrial and research purposes.

This article delves into the importance of graphene, the role of CVD systems

in graphene synthesis, and essential considerations when choosing a graphene CVD

furnace.

Understanding Graphene and Its Importance

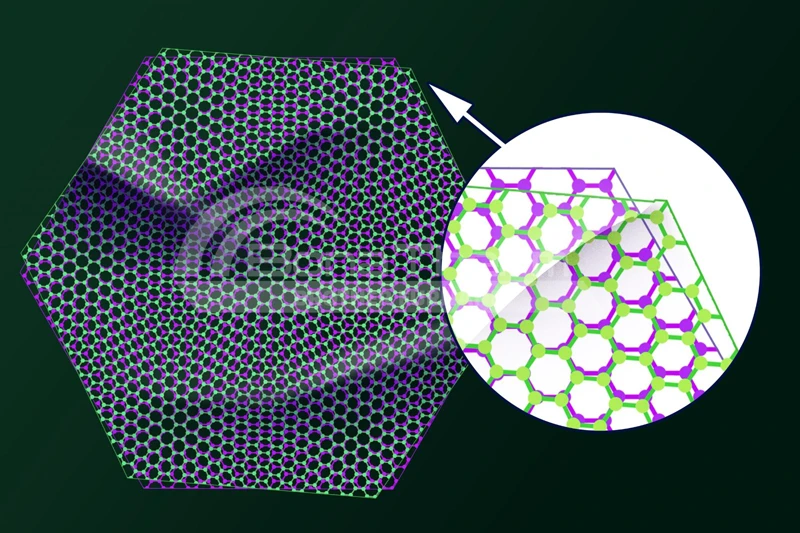

Graphene, an atomic layer of carbon atoms arranged in a hexagonal lattice, has captivated the scientific and industrial communities with its remarkable physical and chemical properties.

This monolayer graphene boasts electrical conductivity superior to most materials, incredible strength, and lightweight characteristics, all while being just one atom thick. Such attributes make it indispensable across various sectors:

1. Electronics: Graphene’s conductivity enables faster and more efficient electronic components, driving advances in next-generation transistors and flexible screens.

2. Energy Storage and Batteries: Due to its surface area and conductive nature, graphene enhances battery efficiency, especially in lithium-ion and supercapacitor technologies.

3. Medicine: In medical applications, graphene’s biocompatibility and flexibility facilitate drug delivery and biosensor development.

4. Composites and Coatings: As a composite material, graphene adds strength while maintaining lightweight properties in products like sports equipment and aerospace components.

Given these uses, the global demand for high-quality graphene continues to

surge, and with it, the need for efficient graphene synthesis. While several

methods exist for producing graphene, chemical vapor deposition (CVD) is highly

favored for its scalability, control over thickness, and purity, making it a

standard for applications requiring contamination-free graphene production.

Overview of the Chemical Vapor Deposition (CVD) Process

Chemical vapor deposition (CVD) is a sophisticated technique for graphene synthesis that involves decomposing hydrocarbon gases like methane in a hot-wall reactor under specific conditions. A substrate, such as copper or nickel, is introduced into the graphene CVD furnace, and with controlled gas flow and high temperatures, a graphene film growth forms on the substrate’s surface. This method is favored for several reasons:

● Scalability and Precision: CVD enables large-scale graphene synthesis with precise control over layer thickness and quality.

● Minimal Contamination: Through an advanced vacuum system and gas supply system, CVD prevents contaminants from affecting the growth process, ensuring high-quality graphene.

● Versatile Substrate Compatibility: The CVD process is compatible with a range of substrates, making it adaptable for different applications.

Features and Benefits of Graphene CVD Furnaces

Graphene CVD furnaces are custom-engineered systems that cater to the exacting requirements of graphene synthesis. They offer several essential features and benefits, enabling researchers and industries to consistently produce premium graphene:

High-Quality Graphene Production: Brother Furnace’s graphene CVD furnace

ensures uniform and defect-free graphene layers. Advanced controls over

temperature and gas flow result in high-purity graphene, essential for

applications with low tolerance for impurities.

Precise Parameter Control for Optimal Graphene Growth: With the ability to control each parameter with accuracy, CVD systems for graphene allow for custom configurations to achieve the desired thickness, quality, and uniformity of monolayer graphene growth.

Advanced Vacuum and Gas Management: Featuring a reliable vacuum system and gas supply system, our furnaces maintain optimal conditions for graphene film growth. The water cooling system further regulates temperatures, preventing overheating and enhancing the durability of the equipment.

Customization Options: Recognizing the unique needs of research and industry, the graphene CVD furnaces from Brother Furnace come with customization options for substrate size, tube furnace configurations, hot-wall reactors, and more. These features enable tailored solutions for specific applications.

Contamination-Free Production: Brother Furnace places a high emphasis on cleanliness, ensuring contamination-free graphene production. This level of quality is essential for sectors where even the smallest impurity can affect product performance.

Key Considerations When Purchasing a Graphene CVD Furnace

To achieve optimal results, selecting the right graphene chemical vapor deposition furnace involves evaluating several critical factors. Here’s a guide

to essential considerations when purchasing a CVD furnace for graphene

production:

Temperature Range and Uniformity: The furnace must maintain high and stable temperatures, which are vital for uniform graphene film growth. A broad temperature range also enables flexibility in production methods, essential for customized applications.

Vacuum and Gas Flow Control Systems: The vacuum system minimizes contaminants and allows for lower pressures, a crucial factor in achieving clean monolayer graphene growth. The gas supply system should offer precise control over gas flow to create ideal synthesis conditions.

Substrate Compatibility and Size: Given the range of substrates used in graphene synthesis, it is essential to ensure that the furnace is compatible with different materials and substrate sizes. The ability to accommodate varying substrate specifications enhances the versatility of the furnace.

Automation and User Interface: Automated control options improve efficiency and reproducibility, especially valuable for industrial-scale graphene synthesis. A user-friendly interface simplifies monitoring and adjustments, making it easier to manage furnace operations.

Safety Features and Compliance with Standards: Operating at high temperatures and handling gas mixtures, CVD systems must incorporate robust safety measures and comply with industry standards to ensure operator safety.

Technical Support and Maintenance Services: Brother Furnace provides comprehensive technical support and maintenance to ensure that our graphene CVD furnaces function at peak efficiency over time. Reliable support is crucial for maintaining consistent quality in graphene production.

Why Choose Brother Furnace’s Graphene CVD Furnace?

As a leading manufacturer in heat treatment and CVD systems, Brother Furnace

specializes in high-quality graphene CVD furnaces designed to support precise

and scalable graphene synthesis.

Our furnaces offer fine-tuned temperature control, advanced vacuum and gas management, and customizable features to match your specific application requirements.

Whether you’re working in a research lab or operating in a large-scale industrial environment, our furnaces ensure consistent, contamination-free graphene production that meets the highest industry standards.

Conclusion

The contribution of graphene CVD furnaces in advancing graphene research and production has been profound. By enabling precise, scalable, and high-purity graphene film growth, these furnaces have cemented their role in numerous industries, from electronics to renewable energy.

Investing in a graphene chemical vapor deposition furnace equips companies and researchers with the tools to explore new applications, enhancing existing technologies and opening doors to innovative solutions that could shape the future.

For industries and researchers exploring the transformative potential of graphene, Brother Furnace offers advanced graphene CVD furnace solutions that are adaptable, precise, and contamination-free.

To learn more about our products and how we can support your graphene production requirements, contact us for a demo or consult our experts for tailored solutions.

With Brother Furnace, your journey toward high-quality, scalable graphene synthesis is well within reach.