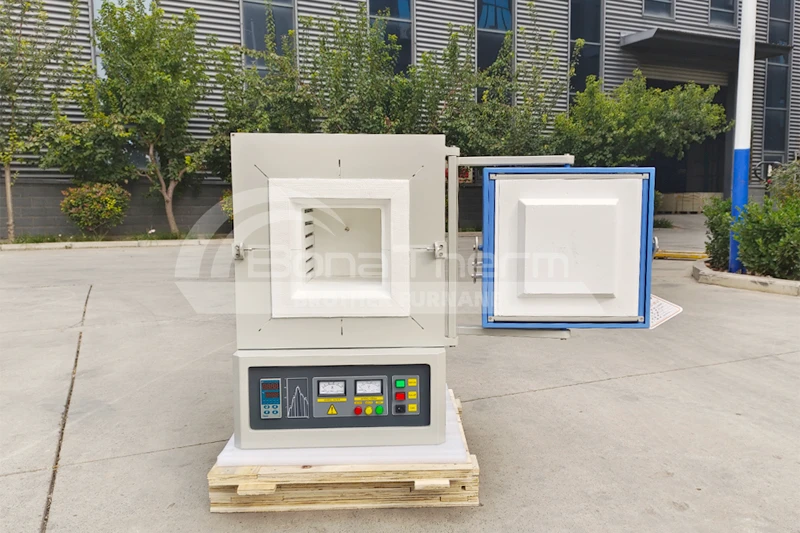

High-Temperature Muffle Furnaces: The Ultimate Guide

A high-temperature muffle furnace is a critical piece of equipment used in a

wide range of industrial and laboratory applications. Defined by its ability to

achieve and maintain extremely high temperatures, a muffle furnace operates with

an enclosed heating chamber, ensuring that the materials being processed are

isolated from combustion by-products.

Historically, muffle furnaces were primarily used for refining precious metals. Over the decades, advances in technology have led to modern versions with sophisticated controls, higher temperature capabilities, and improved efficiency.

High-temperature muffle furnaces play an indispensable role in fields such as metallurgy, ceramics, and scientific research due to their ability to deliver consistent and controlled heating.

In this article, Brother Furnace will further introduce you to high-temperature muffle furnaces.

Key Features and Benefits of High-Temperature Muffle Furnaces

Temperature Range Capabilities

A high-temperature muffle furnace typically operates in the range of 1200°C

to 1800°C, depending on the model and purpose. This wide temperature range makes

it suitable for processes like sintering, annealing, and heat treatment of

metals and ceramics. At Brother Furnace, our furnaces are designed to meet the

most demanding temperature requirements with ease.

Precise Temperature Control

Modern high-temperature muffle furnaces feature advanced programmable controllers that allow users to set and maintain exact temperatures. This precision is crucial in applications where even minor deviations can affect the outcome of the process. With digital PID controllers, our furnaces ensure accurate temperature management for optimal results.

Uniform Heat Distribution

Uniformity in heating is essential for consistent processing. Brother Furnace’s high-temperature muffle furnaces incorporate high-quality heating elements and chamber designs that promote even heat distribution throughout the workspace. This eliminates hotspots and ensures uniform treatment of materials.

Energy Efficiency

Energy efficiency is a key factor when selecting a muffle furnace. Our furnaces are equipped with high-grade insulation materials to minimize heat loss and reduce energy consumption. This not only lowers operational costs but also supports sustainable manufacturing practices.

Durability and Longevity

Investing in a durable high-temperature muffle furnace ensures long-term

reliability and performance. Brother Furnace designs furnaces with robust

construction and high-quality components to withstand prolonged use under

extreme conditions. Our commitment to quality guarantees longevity and minimal

maintenance costs.

Applications and Industries

High-temperature muffle furnaces are indispensable across a wide range of industries. Here are some key sectors where they play a pivotal role:

Materials Science and Metallurgy

In materials science, high-temperature muffle furnaces are used for processes such as sintering, annealing, and stress-relief treatments. Metallurgists rely on these furnaces for heat-treating metals to achieve desired mechanical properties.

Ceramics and Glass Manufacturing

The production of ceramics and glass often requires precise, high-temperature processing. Muffle furnaces are ideal for firing ceramic materials, glazing, and heat-treating specialty glasses.

Aerospace and Automotive Industries

High-performance materials used in aerospace and automotive components must undergo rigorous heat treatment. High-temperature muffle furnaces ensure that these components meet stringent quality and performance standards.

Electronics and Semiconductor Production

In electronics manufacturing, muffle furnaces are used for processes like

oxide layer formation and thermal oxidation. The ability to maintain clean and

controlled environments is crucial for semiconductor applications.

Research and Development Laboratories

Research labs across various fields depend on high-temperature muffle furnaces for experiments requiring precise thermal processing. From material testing to chemical analysis, these furnaces provide reliable performance for R&D purposes.

How to Choose the Right Muffle Furnace

Selecting the right high-temperature muffle furnace involves considering several factors to ensure it meets your specific needs:

Determining Temperature Requirements

Identify the maximum temperature needed for your processes. Brother Furnace offers a range of furnaces designed to handle different temperature thresholds, from 1200°C up to 1800°C.

Assessing Chamber Size and Capacity Needs

Consider the size and volume of materials you plan to process. Our furnaces come in various chamber dimensions to accommodate different batch sizes and workflows.

Considering Heating Element Types

Different applications may require specific heating elements, such as silicon

carbide or molybdenum disilicide. Brother Furnace provides options to match your

exact requirements.

Evaluating Control Systems and Programmability

Look for furnaces with user-friendly control systems. Programmable controllers with multiple heating profiles can significantly enhance operational efficiency.

Maintenance and Safety Tips

Proper maintenance ensures the longevity and safe operation of your high-temperature muffle furnace. Here are essential tips:

Regular Cleaning and Inspection Procedures

Keep the furnace chamber clean to prevent contamination. Regularly inspect heating elements and insulation for wear and tear.

Proper Loading and Unloading Techniques

Always use appropriate tools and protective equipment when handling hot materials to avoid damage and injury.

Temperature Calibration and Monitoring

Regularly calibrate the furnace to ensure accurate temperature readings. Use

reliable thermocouples and monitoring systems.

Safety Precautions and Protective Equipment

Wear heat-resistant gloves, goggles, and other protective gear. Ensure that the furnace area is well-ventilated and equipped with fire safety measures.

Troubleshooting Common Issues

Familiarize yourself with common problems such as heating element failure or controller errors. Refer to the user manual or consult Brother Furnace’s technical support for assistance.

Brother Furnace: Your Trusted Partner in High-Temperature Solutions

Investing in a high-quality high-temperature muffle furnace is essential for achieving precision and reliability in your heat treatment processes. Brother Furnace, as a leading manufacturer, offers a range of muffle furnaces designed to meet the needs of diverse industries.

For more information, or to discuss your specific requirements, our team of experts is ready to help you find the ideal solution. Welcome to contact us. Ensure your operations benefit from the quality and performance of Brother Furnace’s high-temperature muffle furnaces.