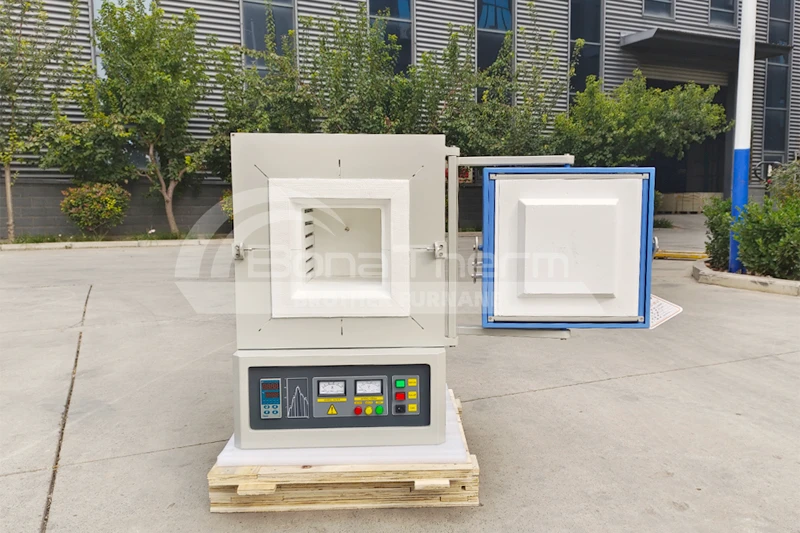

Lab Sintering Box Furnace: Powering Innovation in Materials Science

Sintering is a critical process in materials science that transforms powdered

substances into solid structures by applying heat just below their melting

points.

This process enhances material properties such as density, strength, and thermal conductivity, making it invaluable across various industries, from ceramics to electronics. For researchers and small-scale production teams, lab sintering box furnaces are indispensable tools.

These compact, high-precision furnaces bring efficiency and accuracy to material development, enabling innovation and driving advancements in science and technology.

In this comprehensive guide, Brother Furnace will explore the features, benefits, applications, and considerations for selecting a lab sintering box furnace, while emphasizing its role in shaping the future of materials science.

Understanding Sintering and Lab Sintering Box Furnaces

Sintering is fundamental in materials science, especially for developing high-performance materials. The process involves heating powdered materials under controlled conditions to improve their physical properties. Applications range from ceramic firing to nanomaterial synthesis, each requiring precise control over temperature and environment.

Lab sintering box furnaces are designed to meet the demands of this intricate

process. These compact design furnaces combine advanced heating technology with

precise atmosphere control, providing the flexibility needed for laboratory

research and small-scale industrial production.

Key Features of Lab Sintering Box Furnaces

High-Temperature Capabilities (Up to 1800°C)

The ability to reach extreme temperatures, often as high as 1800°C, is a hallmark of high-temperature lab furnaces. This feature makes them ideal for sintering applications that demand elevated temperatures, such as powder metallurgy and heat treating. The capability to operate at such high temperatures ensures compatibility with a wide range of materials.

Precise Temperature Control and Uniform Heating

Temperature consistency is crucial in achieving desired material properties. Lab sintering box furnaces are equipped with advanced control systems that maintain tight tolerances, ensuring uniform heating across the entire chamber. This precision reduces variability and improves the reproducibility of results, a key factor in research and development.

Atmosphere Control Options

Many sintering processes require a specific atmosphere to prevent oxidation or promote chemical reactions. Modern box furnaces provide customizable atmosphere control, allowing users to create inert, reducing, or oxidizing environments. This flexibility is essential for processes like nanomaterial synthesis and ceramic firing.

Compact and Efficient Design

Designed for laboratory environments, these furnaces are compact yet

powerful. Their compact design allows them to fit seamlessly into research labs

or small production setups, maximizing workspace efficiency without sacrificing

performance.

Advanced Heating Elements and Insulation Materials

To optimize energy use and durability, lab furnaces utilize advanced heating elements and high-performance insulation materials. These components enable rapid heating, reduce energy consumption, and ensure long-term reliability, making these furnaces both cost-effective and environmentally friendly.

Benefits of Using Lab Sintering Box Furnaces

Enhanced Material Properties

Sintering in a lab sintering box furnace allows researchers to control the microstructure and mechanical properties of materials, resulting in products with improved density, strength, and thermal stability. This precision is especially valuable in industries such as aerospace and electronics, where material performance is critical.

Versatility in Research and Development

These furnaces are incredibly versatile, supporting applications ranging from heat treatment to nanomaterial synthesis. Their adaptability makes them ideal for exploring new materials, developing prototypes, and fine-tuning manufacturing processes.

Improved Energy Efficiency

Compared to traditional industrial furnaces, high-temperature lab furnaces

are designed to optimize energy use. With efficient insulation and targeted

heating, these systems minimize energy wastage, reducing operational costs and

environmental impact.

Increased Productivity and Reproducibility

Reproducibility is essential in both academic research and industrial production. The uniform heating and precise controls of lab furnaces ensure consistent results, reducing the need for rework and accelerating project timelines.

Cost-Effective Solution

For laboratories and small-scale production facilities, lab sintering box furnaces offer a cost-effective alternative to larger, more complex systems. They deliver high performance and reliability at a fraction of the cost, making them accessible to a wide range of users.

Applications of Lab Sintering Box Furnaces

Ceramics and Advanced Materials

Ceramic firing relies heavily on precise temperature control to achieve optimal hardness, thermal resistance, and durability. Lab sintering box furnaces are ideal for processing ceramics, whether for industrial components or artistic applications.

Powder Metallurgy

In sintering applications for powder metallurgy, these furnaces enable the

production of high-density, high-strength metal parts. Their ability to control

temperature and atmosphere is critical for creating components with excellent

mechanical properties.

Electronics and Semiconductor Manufacturing

The electronics industry depends on lab furnaces for processes like sintering conductive materials and developing high-performance electronic components. These furnaces are indispensable in research and prototyping for semiconductors.

Aerospace and Automotive Industries

Lightweight, durable materials are essential in aerospace and automotive manufacturing. High-temperature lab furnaces support the sintering of advanced composites and metal alloys, enabling the production of components that meet stringent performance requirements.

Biomedical Research and Implant Development

In the biomedical field, sintering is used to create biocompatible materials for implants and prosthetics. Lab sintering box furnaces allow researchers to develop materials with the precise properties needed for medical applications, such as controlled porosity and strength.

How to Choose the Right Lab Sintering Box Furnace

Selecting the ideal lab sintering box furnace involves careful consideration

of your specific needs:

Assessing Temperature Requirements

Understand the maximum temperature your application demands. For processes that require furnaces up to 1800°C, ensure the furnace can operate at the necessary levels without performance degradation.

Considering Chamber Size and Capacity

Evaluate the volume and size of materials you’ll process regularly. A furnace with the right chamber size will optimize energy use and ensure efficient operation.

Evaluating Atmosphere Control Options

Different sintering processes may require specific atmospheres. Ensure the furnace includes the atmosphere control features needed for your applications, whether inert, reducing, or oxidizing.

Analyzing Heating Rates and Cooling Capabilities

The ability to control heating and cooling rates can significantly impact material properties. Choose a furnace with customizable options to suit your specific requirements.

Reviewing Safety Features and Compliance

Ensure the furnace includes robust safety features, such as over-temperature protection, and complies with industry standards. This is crucial for maintaining a safe and compliant laboratory environment.

Why Brother Furnace?

Brother Furnace specializes in designing and manufacturing state-of-the-art

lab sintering box furnaces tailored to meet the needs of researchers, engineers,

and manufacturers. Our furnaces combine cutting-edge technology with

user-friendly features, ensuring reliable performance and outstanding

results.

Our products include:

● High-temperature lab furnaces for temperatures up to 1800°C

● Models with customizable atmosphere control and compact designs

● Systems designed for applications like ceramic firing, heat treating, and nanomaterial synthesis

We pride ourselves on delivering exceptional value and comprehensive support to our clients. Whether you need a standard furnace or a fully customized solution, Brother Furnace has the expertise to help you succeed.

Conclusion

The lab sintering box furnace is an indispensable tool for modern materials science, offering unmatched precision, efficiency, and versatility. Its applications span a wide range of industries, from electronics and aerospace to biomedical research, driving innovation and enabling breakthroughs.

By choosing a high-quality lab sintering box furnace from Brother Furnace, you can unlock the potential for advanced research and small-scale production while benefiting from reliable performance and expert support.

Contact us today to explore our range of furnaces and find the perfect solution for your needs. Brother Furnace will help you power innovation in your laboratory or production facility!