Why Choose a PECVD Machine?

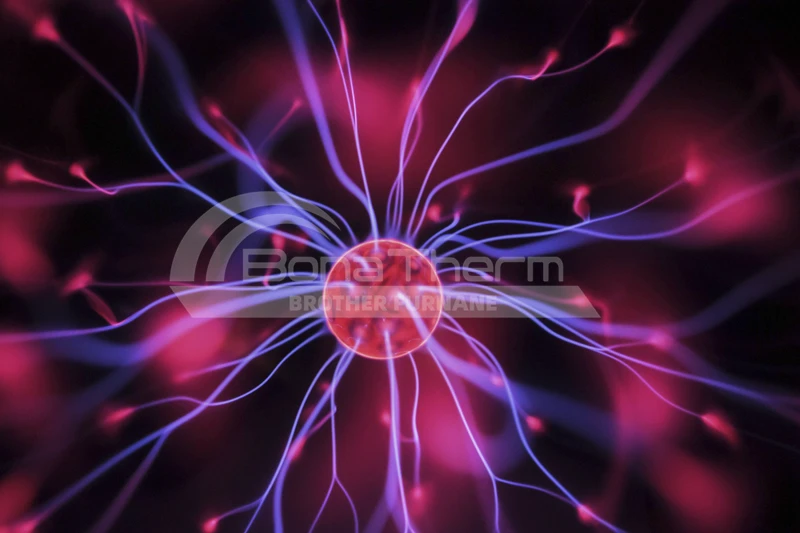

Plasma-Enhanced Chemical Vapor Deposition, or PECVD, has emerged as a

transformative process in the world of thin film deposition, powering industries

from semiconductors to biomedical applications.

As plasma-enhanced chemical vapor deposition leverages plasma to activate chemical reactions at reduced temperatures, it enables high-quality thin films on diverse substrates, overcoming the limitations of traditional chemical vapor deposition.

For industries where precision, material versatility, and adherence to stringent standards are paramount, PECVD machines provide a unique advantage, making them essential for advanced manufacturing and research.

This article explores the advantages of PECVD systems, their critical features, applications, and considerations when choosing the right machine. By understanding these aspects, businesses can unlock the potential of PECVD equipment to optimize production quality and operational efficiency.

As a professional manufacturer, Brother Furnace brings unmatched expertise in

producing reliable PECVD machines that cater to specific industrial

requirements.

Benefits of PECVD Machines

The advantages of PECVD machines are multifaceted, offering unparalleled quality, efficiency, and versatility in film deposition. Here are some of the significant benefits that make PECVD equipment a top choice in thin film deposition:

Enhanced Film Quality and Uniformity

PECVD systems utilize plasma to create a more reactive gas environment, resulting in exceptionally smooth, uniform films. This leads to fewer surface defects, improved optical clarity, and greater control over film properties. For industries such as optical coatings and semiconductor manufacturing, precise film uniformity is crucial, impacting product performance and longevity.

Lower Processing Temperatures

One of the distinct advantages of PECVD machines over other deposition methods is their lower temperature requirements. This enables the deposition of thin films on temperature-sensitive materials like plastics, reducing the risk of material deformation or damage. In biomedical applications, for example, PECVD can be used to coat delicate instruments without compromising their integrity.

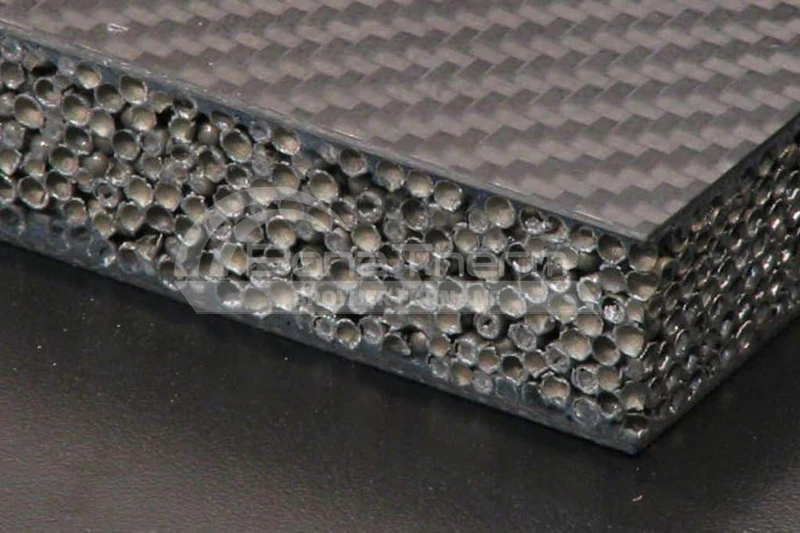

Improved Adhesion and Density of Deposited Films

PECVD equipment creates high-density coatings with excellent adhesion

properties, which is vital in applications where durability is essential. By

generating a strong bond between the substrate and the deposited material, PECVD

enhances the wear resistance of films, ideal for protective coatings on tools

and industrial components.

Material Deposition Versatility

One of the defining characteristics of plasma-enhanced chemical vapor deposition is its ability to deposit a wide range of materials, from diamond-like carbon (DLC) coatings to advanced carbon-based nanomaterials. This versatility has made PECVD a popular choice for emerging fields such as graphene deposition and carbon nanotube (CNT) production, where precise control over material composition and structure is critical.

Cost-Effectiveness in Long-Term Operations

While PECVD machines represent a significant upfront investment, the long-term operational cost savings they offer can be substantial. By allowing multi-layer coatings in a single cycle, PECVD equipment minimizes downtime and reduces the need for multiple deposition processes, resulting in lower material waste and more efficient production.

Key Features to Consider in PECVD Machines

Choosing the right PECVD machine for your specific requirements depends on understanding the essential features that contribute to performance and reliability:

Plasma Source and Power

The type of plasma source used in PECVD systems directly affects the film

deposition process. RF and microwave plasmas are popular, with each suited to

different materials and deposition requirements. High-power sources allow for

faster and more efficient coatings, while lower power may be suitable for

sensitive applications.

Chamber Design and Size

Chamber design impacts how uniformly the plasma is distributed, which is vital for ensuring consistent film thickness across substrates. When considering PECVD equipment, look for chamber designs that promote even plasma flow and reduce contamination risks.

Gas Delivery System

Precise control over gas flow and composition is essential for high-quality thin film deposition. A reliable gas delivery system that can introduce a variety of reactive gases, such as silane, methane, or nitrogen, is crucial for customizing film characteristics.

Substrate Heating and Cooling Capabilities

Temperature management is key in PECVD processes, especially for materials that may be sensitive to thermal stress. Advanced PECVD machines incorporate precise heating and cooling mechanisms, ensuring that substrates remain stable during deposition and enhancing the final product’s durability.

Process Control and Monitoring Systems

Real-time monitoring and automated control systems in PECVD systems allow operators to fine-tune deposition parameters and respond to changes promptly. This helps maintain consistency in film quality and increases production yield.

Automation and User Interface

User-friendly interfaces and automation capabilities streamline PECVD

operations, allowing for more efficient and less labor-intensive processes. With

intuitive controls and pre-programmed settings, automated PECVD equipment can

handle complex multi-layer coatings, making it suitable for large-scale

production environments.

Applications of PECVD Technology

The versatility of PECVD machines makes them indispensable across a range of industries. Here are some primary applications:

Semiconductor Manufacturing

PECVD is widely used in semiconductor fabrication for applying insulating layers, passivation layers, and other functional films on electronic devices. The precision of PECVD equipment ensures minimal defects, which is critical in high-performance electronics.

Solar Cell Production

In the renewable energy sector, PECVD systems are essential for depositing anti-reflective coatings on solar cells, increasing their efficiency by minimizing energy loss. PECVD also allows for the deposition of thin-film silicon layers, which are used in advanced photovoltaic cells.

Optical Coatings

The ability to deposit transparent, scratch-resistant, and anti-reflective coatings makes PECVD a valuable technology in the optics industry. PECVD machines are used to create durable films for lenses, mirrors, and other optical components.

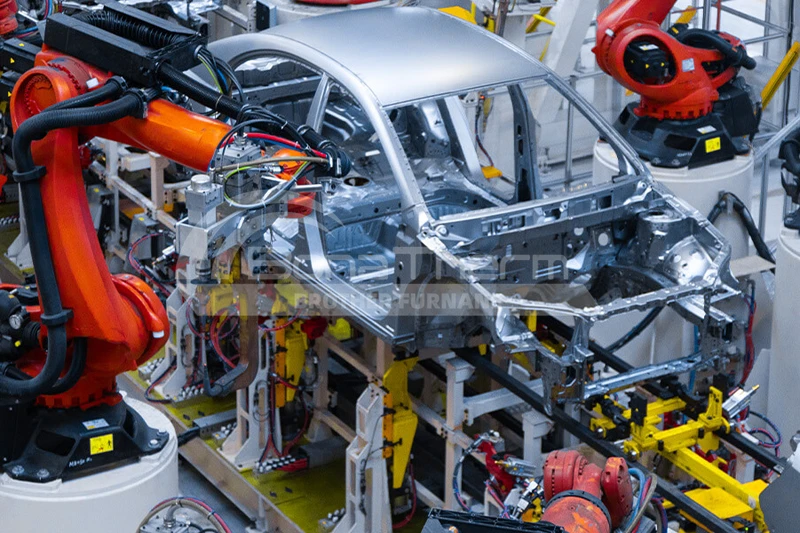

Protective Coatings for Tools and Components

PECVD equipment is ideal for depositing diamond-like carbon (DLC) coatings,

which provide excellent hardness and wear resistance. These coatings are widely

used in the automotive and aerospace industries to extend the life of critical

components.

Biomedical Applications

PECVD enhances the biocompatibility of medical devices by creating films that can resist wear, corrosion, and bacterial adhesion. In this way, PECVD supports the development of advanced implants, stents, and surgical instruments.

Nanotechnology Research

PECVD is instrumental in nanotechnology, enabling the precise deposition of carbon nanotubes (CNTs) and graphene layers. These materials are essential for innovations in electronics, materials science, and energy storage.

Conclusion

In an era where precision, efficiency, and versatility are paramount, PECVD machines have solidified their role in thin film deposition. By allowing precise control over film properties, PECVD systems empower industries ranging from semiconductors to nanotechnology to advance their manufacturing capabilities.

As a trusted manufacturer of PECVD machines, Brother Furnace is dedicated to

providing state-of-the-art solutions that meet the unique needs of diverse

industries.

Whether you are exploring options for thin film deposition on temperature-sensitive materials or seeking advanced capabilities for nanotechnology research, Brother Furnace has the expertise and quality assurance to support your goals.

For those considering a new PECVD system or looking for PECVD furnaces, Brother Furnace encourages you to contact us.

With a commitment to quality, innovation, and customer satisfaction, Brother Furnace is your partner in achieving excellence in plasma-enhanced chemical vapor deposition technology.